Thermal Transfer Overprinting for Flexible Packaging Coding: The Ultimate Guide

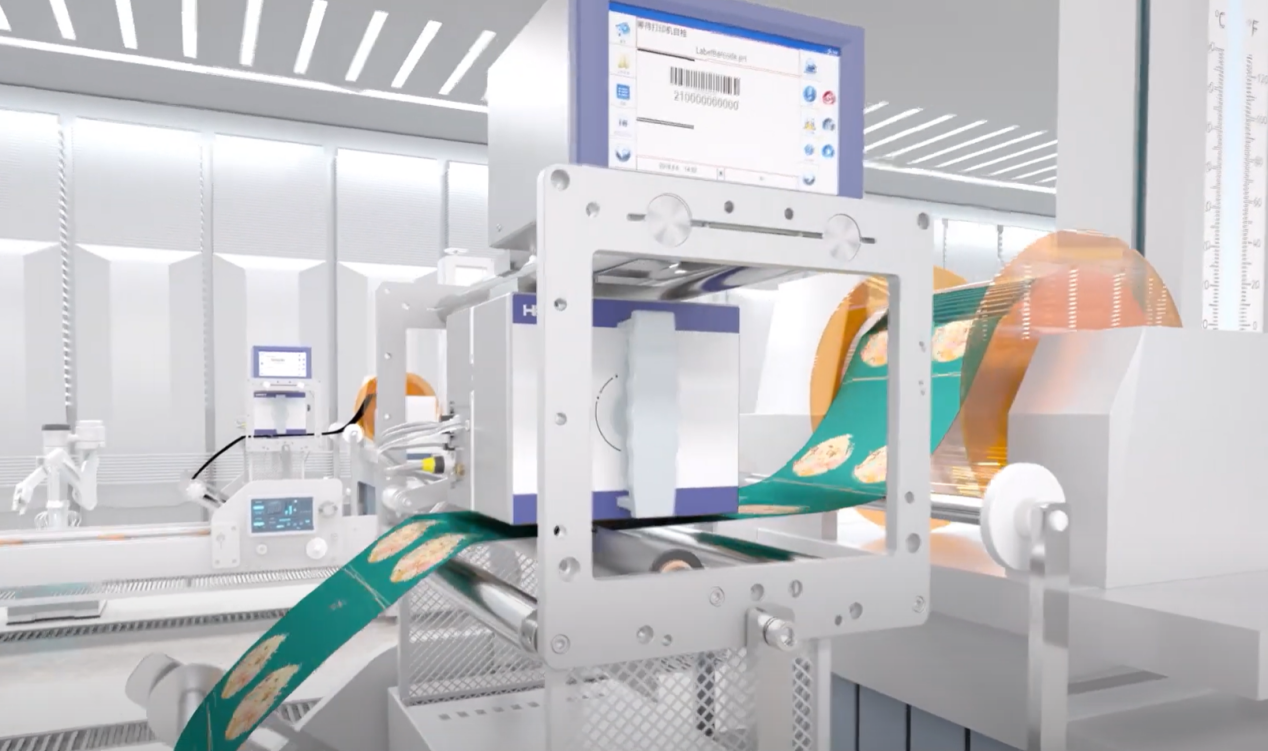

Thermal Transfer Overprinting (TTO) is an important flexible packaging coding method, particularly in the food industry. Snack foods and other packaged goods such as chips and biscuits benefit immensely from this economical and efficient technology. This guide helps you understand the suitable materials and types of flexible packaging for TTO printers, as well as the quality of their coding results.

Flexible Packaging Materials Compatible with TTO Printers

TTO printers work by using thermal transfer ribbons and a heated print head to transfer ink onto the film. The printed information—be it text, barcodes, or graphics—adheres firmly to the flexible packaging. Even under conditions of high temperature, humidity, and friction, the print remains crisp and readable throughout the product's lifecycle.

TTO printers demonstrate exceptional versatility in handling a wide variety of flexible packaging materials. Their range extends from plastic films like PVC, PET, PE, PP, NY, CPP, OPP, BOPP, BOPET, BOPA, CPP, and PE to aluminum foil and paper.

Generally, the selection of these flexible packaging materials is guided by a combination of product characteristics, packaging requirements, and environmental considerations.

Types of Flexible Packaging Suitable for TTO Printers

Flexible packaging varies extensively and is used across industries like food, daily chemicals, and pharmaceuticals. Common types include:

● Stick Packs: Ideal for single-serving condiments, sauces, and coffee creamers.

● Sachets: Suitable for samples, spices, pharmaceuticals, and cosmetics.

● Quad-seal Bags: Often used for bulk foods, grains, and pet food.

● Flow Bags: Typically used for individually wrapped candies, biscuits, and lollipops.

● Pouch Packs: Appropriate for liquids, sauces, pastes, and other fluid or semi-fluid products.

● Brick Bags: Commonly used for vacuum-packed coffee, tea, and powdered milk..

● Pillow Bags: Perfect for packaging snacks like chips, biscuits, and bread.

● Flat Bottom Bags: Frequently used for premium snacks and pet foods.

● Gusseted Bags: Suitable for bulky items.

● Spouted Pouches: Ideal for beverages, sauces, and detergents that need to be poured or squeezed out.

TTO Printing Effect (Including pictures)

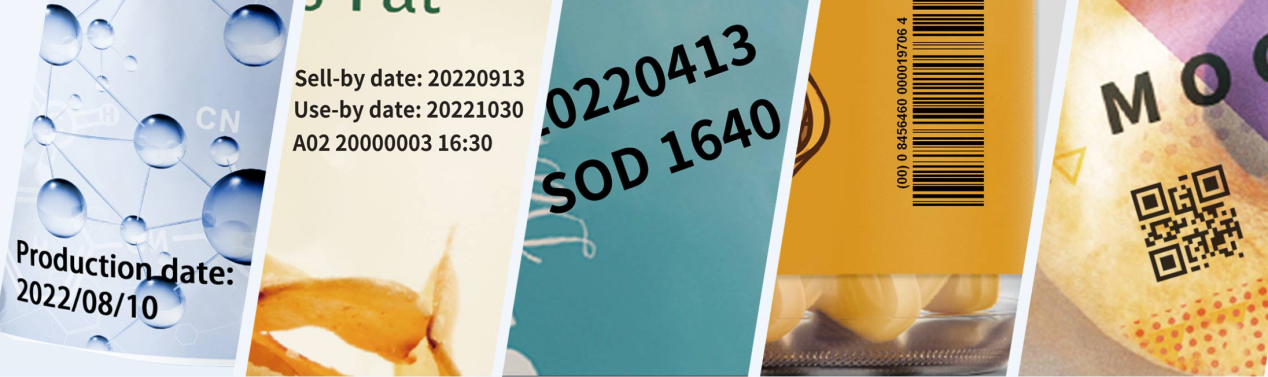

Compared to other printing technologies like inkjet coding, thermal transfer overprinting provides a distinct advantage in terms of print quality and durability. It maintains clarity and readability even in environments with high temperatures, perspiration, alcohol, friction, or temperature changes.

While inkjet coding uses a dot matrix approach that might be limited in print clarity and detail, TTO provides superior print quality, producing finer text and graphics.

Besides standard date and batch coding, TTO is particularly adept at printing high-definition QR codes, barcodes, and detailed graphic content like complex nutrient facts tables.

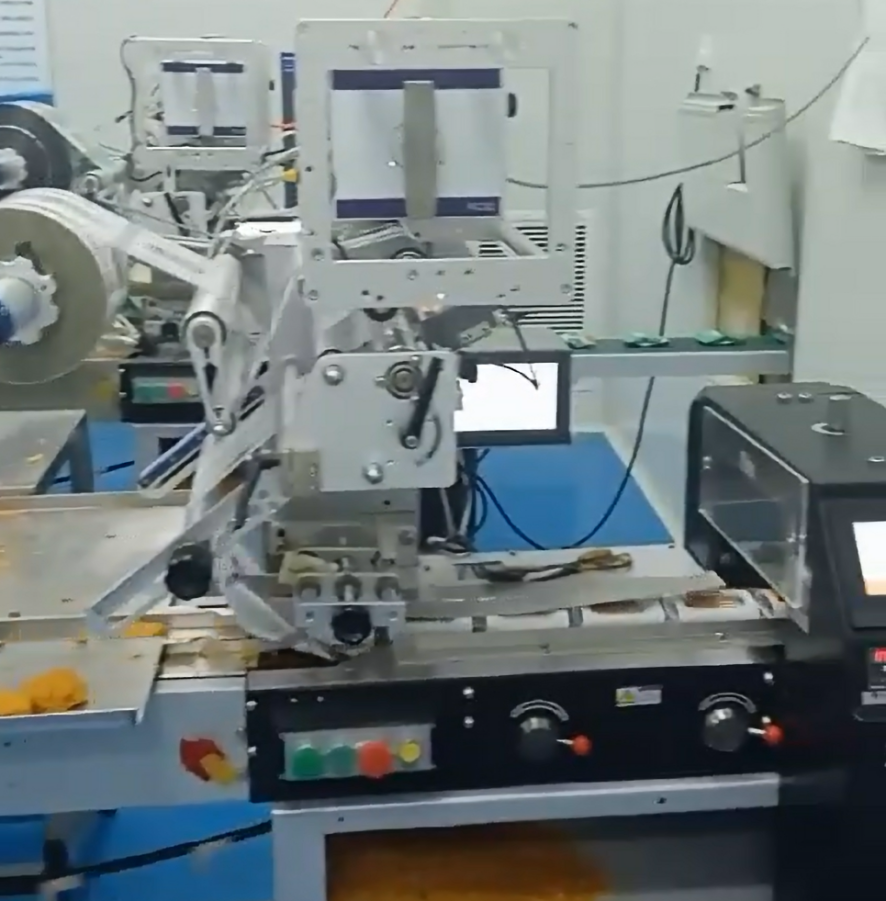

HPRT TTO printers are built with high-quality components, offering durability and low maintenance costs.

These automatic batch coding machines are available in both continuous and intermittent models, suitable for factory workshops and automated production lines in flexible packaging. They are extensively used across food, pharmaceutical, and personal care industries, with outstanding coding results.

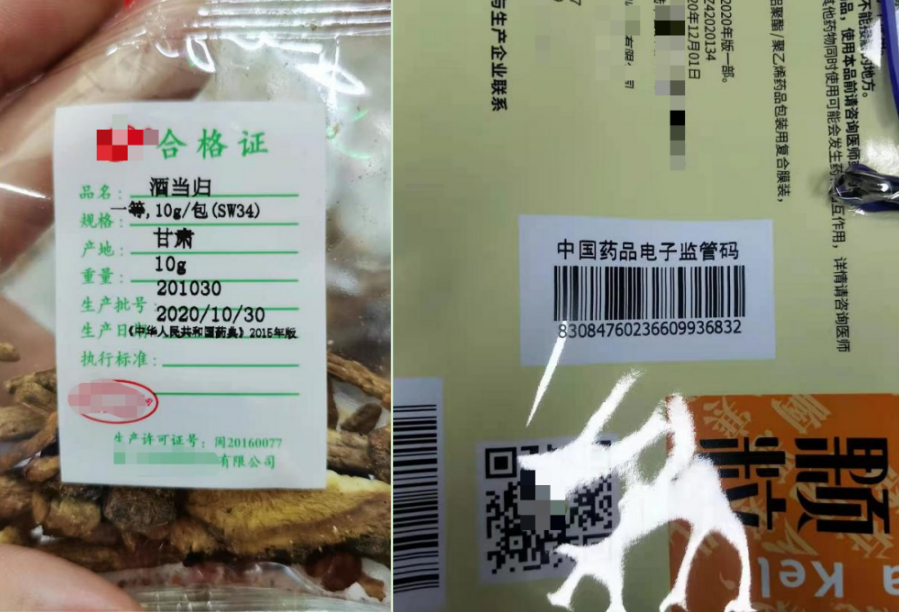

Here are some real-world examples of thermal transfer coding effects produced by our date coding machines.

1. Food Packaging Coding: Ideal for snacks, pastries, sauces, mooncakes, and other types of flexible film packaging.

Recommended Product: The HPRT FC53 series TTO printer, which integrates seamlessly with pillow packaging machines, horizontal packaging machines, pagination machines, labeling machines, and filling machines, offers 300dpi high-resolution printing at speeds up to 600mm/s.

2. Pharmaceutical Packaging Coding: Suitable for traditional herbal slices and printing regulatory codes.

3. Tissues and Mask Product Coding: Ideal for essential hygiene products such as face masks, tissues, wet wipes, cotton swabs, and makeup remover pads.

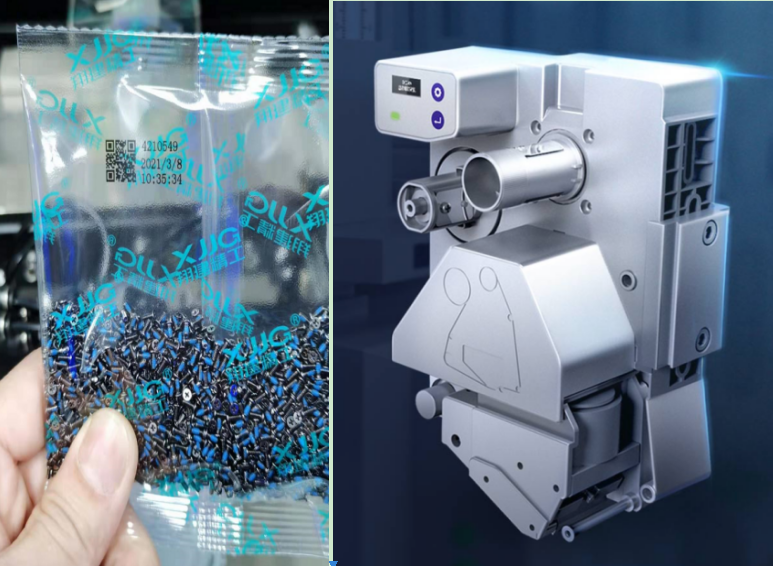

4. Plastic and Hardware Packaging Coding: Optimal for coding on flexible film packaging of screws, precision small parts, and electronic components.

Recommended Product: The HPRT DC24A-E intelligent date coder, compatible with vertical packaging machines, is ideal for printing date codes and batch numbers in small areas.

5. Household Chemical Product Coding: Suitable for items such as desiccants, preservatives, and self-heating packs.

If you are seeking a flexible packaging coding solution or need to purchase an economical and efficient TTO printer, contact us today for a free consultation and quote!