An Introduction to Thermal Transfer Overprinting (TTO) Ribbon

The thermal transfer overprinting ribbon is a layer of PET film coated with fusible ink on one side and a protective layer called a back coating on the other side.

TTO ribbon is generally composed of the front lead ribbon (handle), the original ribbon, the rear lead ribbon, and the shaft core. The front lead ribbon (handle) is in front of the original ribbon, and the rear leader is at the end of the ribbon roll (some ribbons do not have a rear leader).

The Front Lead Ribbon

The front lead ribbon is generally transparent and has the following functions:

It is convenient to install the ribbon on the printer;

Product names, company names and trademarks can be printed as product identifications on it for marketing;

It can protect the ribbon.

The Original Ribbon

The original ribbon generally consists of five layers.

Top coating

It is mainly used to improve the adhesion of ink on the printing target medium and enhance the resistance against the environment;

Ink layer

It is used to print and determine the characteristics of the ribbon;

Inner coating

It is mainly used to smooth the printed surface and keep the consistency of the ink released from the ribbon base;

Ribbon base

It is the carrier of other layers as well as the main determinant of thermal conductivity;

Back coating

To put it simply, it is a special coating applied to the back of the ribbon, whose main function is to reduce the wear of the print head, reduce static electricity generation and enhance heat conduction.

The Rear Lead Ribbon

The rear leader generally acts as a warning, allowing the printer to sense the end of the ribbon. Different printers use different rear lead ribbons. There are mainly three types.

Aluminized (silver): It is mainly suitable for thermal transfer printers that use a reflective sensor to detect the end of the ribbon. When it receives a strong reflected light, it means the end of the ribbon.

Transparent: For transmissive sensors, allowing light to pass through indicates the end of the ribbon.

Mechanical Sensing: The printer senses the end of the ribbon through the changes in tension.

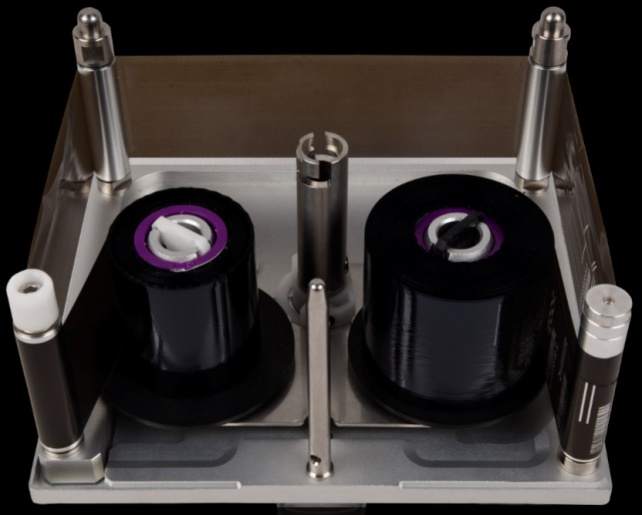

Shaft Core

The most common types of ribbon cores are paper-made shaft cores and plastic-made shaft cores. The major requirement for the shaft core is that it cannot be deformed or slipped during printing.

HPRT has developed a cost-effectibe thermal transfer ribbon for the self-developed TTO printers. If you need more infomation about TTO ribbons,please contact us. We’re more than happy to provide free consultation on thermal transfer overprinters and ribbon solutions for you.