Can You DTG Print on Polyester T-Shirts?

Direct-to-Garment (DTG) printing has upended the world of textile printing, bringing a fresh array of advantages to the fore. Still, when it comes to implementing this technology on specific fabrics like 100% polyester, the waters can get somewhat choppy. In this journey of exploration and explanation, we’ll delve into the intricacies of why DTG printing on 100% polyester presents such challenges, and provide a simple guide to the DTG printing process on polyester T-shirts.

Why DTG on 100% Polyester is Challenging

DTG printing is a process where ink is applied directly onto fabric using specialized printers. These printers use inks specially formulated to be compatible with natural fibers like cotton and polyester. However, DTG on 100% polyester, especially darker fabrics, can be tricky due to the fabric’s unique properties and the way the ink interacts with it.

Unlike cotton, which has a tighter weave that allows the ink to fully saturate the fabric, polyester has a looser weavethis that is great for moisture wicking and breathability. This means that less ink can penetrate the fabric, especially when using white ink on darker polyester fabrics. This means ink that is initially printed into the gaps between the fibers will wash away during the first washing. The result can be a grayish or washed-out appearance. Printers often recommend using a blend of 50% polyester or a tri-blend T-shirt for DTG printing, as these fabrics absorb the ink better than 100% polyester.

When printing on colored polyester garments, there’s the risk of dye migration. This occurs when the dye from the polyester bleeds into the print during the curing process. For instance, if white ink is used on a red T-shirt, the print may appear pink. To prevent this, the curing temperature must be set lower than what would typically be used for cotton or other natural fabrics.

How to Print DTG on Polyester T-Shirts

Now, let’s meticulously explore each stage involved in the process of DTG printing on polyester T-shirts.

Pre-treatment:

Before initiating the Direct-to-Garment (DTG) printing process on polyester garments, pre-treatment is an essential preliminary step that should not be overlooked. This involves applying a specific polyester pre-treatment solution to the T-shirt, followed by an adequate drying period.

The primary objective of this pre-treatment is to ensure the best possible print quality on polyester fabrics. Unlike cotton, where ink can seep readily into the material, polyester’s denser weave makes the ink tend to settle on its surface. This characteristic of polyester necessitates a thorough pre-treatment for achieving exceptional print outcomes. It assists in building a robust base, facilitating superior ink adherence to the fabric.

Moreover, the significance of pre-treatment is further amplified when utilizing white ink in DTG printing, especially for darker garments. Following the first pre-treatment, a white ink layer is applied, setting a strong groundwork for the upcoming colors. This white ink layer augments color vibrancy and opacity, particularly on dark polyester fabrics.

DTG Printing:

Once the pre-treated garment is dry, it’s time to print. In this step, your design is uploaded into the printer, and the inks are applied directly onto the fabric using specialized printers and heat presses.

The inks utilized for this process are tailored specifically to polyester. This enables their direct application, avoiding any potential harm to the garment, distinguishing this process from cotton printing which may require different ink varieties.

A uesful practice to ensure a clean and precise print is to unfold the garment, creating a clear workspace for the printer to maneuver. This method ensures the rear side of the print area remains untouched during the printing process. By doing so, it helps diminish the chance of ink seeping through from the front to the back, thereby significantly reducing the risk of dye migration.

Curing:

After the application of the desired colors, the next step is curing. This involves using heat lamps to set the inks permanently onto the garment and heating time should last about the time the ink manufacturer suggests.

However, when dealing with polyester, it’s imperative to adjust the curing temperature to a setting lower than the standard one used for cotton or other organic fabrics. This is done to prevent dye migration, a common issue when printing on colored polyester garments.

To illustrate, if white ink is employed on a red polyester T-shirt without modifying the curing temperature, dye migration might occur, leading to a pinkish print. In contrast, cotton fabrics are less susceptible to this problem, permitting the use of higher curing temperatures.

Upon completion of the curing process, the garment can be subjected to washing. This action aids in softening both the print and the fabric, enhancing the comfort of the wearer.

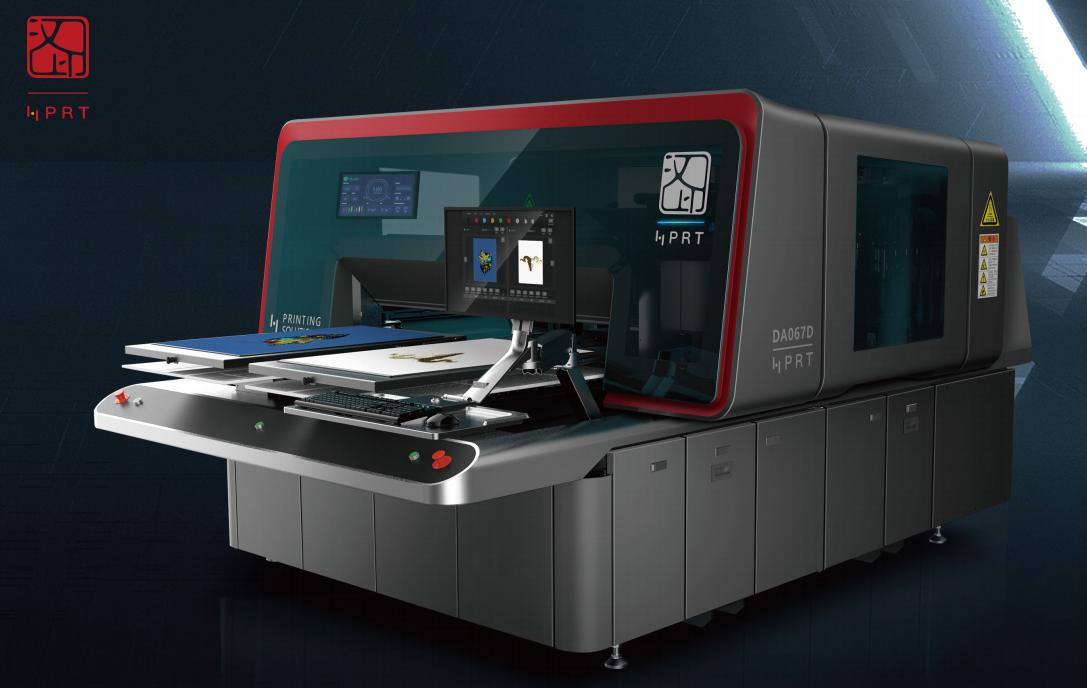

DTG on Polyester Printer HPRT DA067D

If you’re looking to print designs on polyester T-shirts, the DA067D is the perfect printer for the job. Its advanced direct-to-garment printing capabilities, combined with the use of pigment ink, ensure exceptional results on polyester fabric.

With a generous maximum print width of 600x900mm (or 400x500mm with the standard plate), you can efficiently create and print large designs on polyester T-shirts. Whether it’s intricate artwork or bold graphics, the DA067D can handle it with ease.

Moreover, the versatility of the DA067D extends beyond polyester. You can also utilize this printer to print on various other fabrics, including cotton, polyester cotton blends, Lycra, rayon, silk, leather, denim, flax, wool, elastic fabrics, and even new fiber types.

If you have any printing issues with DTG, please feel free to contact usfor professional support.

It’s worth noting that while the process for DTG printing on polyester can be a bit more complex than that for cotton, the end result can offer unique benefits such as a smoother finish to the print and greater durability, making it a popular choice for sportswear and other high-usage applications.

Final Thoughts

Despite the challenges, advancements in DTG printer technology coupled with breakthroughs in new inks have changed printing on polyester shirts dramatically. Now, one can offer customization of polyester shirts with no minimum quantity order, no dye migration, superior white base transparency with lasting, realistic graphics, and prints available in a broader variety of polyester fabrics and textures.

While DTG printing on 100% polyester, particularly darker shades, may have its challenges, with the right pre-treatment, temperature setting, and attention to detail, these obstacles can be overcome. Moreover, the advancements in DTG technology and inks have opened up new possibilities, making this an exciting area for innovation and exploration.