Direct-to-Garment Printing Guide: Everything You Know (in 2023)

Direct-to-Garment (DTG) Printing is everywhere. From custom t-shirts to sports apparel, and even high-end fashion, DTG printing has become a popular printing method for producing high-quality, full-color prints directly onto garments. With its versatility and ability to reproduce intricate details and vibrant colors, DTG printing has revolutionized the world of custom apparel and fashion.

In this blog, we will cover:

--What is Direct-To-Garment (DTG) Printing?

--The Process of DTG Printing

--Benefits & Applications of DTG Printing

--DTG Printer Buying Guide

What is direct-to-garment (DTG) printing

Direct-to-garment printing is a method of printing digital images directly onto garments using specialized inkjet technology. In this process, a digital image is printed directly onto a garment, such as a t-shirt, using a specialized DTG printer that applies water-based inks to the fabric.

In the printing process, the fabric surface is colored with inks by the printheads, resulting in a high-quality, long-lasting print that looks and feels like it is part of the garment. A direct-to-garment printer is often used for customized or personalized apparel, such as t-shirts, hoodies, and other types of clothing.

The process of DTG Printing

In comparison to screen printing, the process of DTG printing is pretty simple and time-saving. It involves four steps, which are quite similar to those in DTF (direct-to-fabric) printing. If you are interested in the process of DTF, please click here for details. Now let’s briefly introduce the process of DTG printing.

1.Pre-treatment

Pre-treatment for DTG printing is essential. DTG inks are going to adhere better to the garment through it. Since that cotton and water-based pigment inks are the most common match in direct-to-garment printing, the pre-treatment here is quite simple, compared to DTF utilizing various types of fabrics and inks.

Specifically, proper pre-treatment solutions spray garments by a dedicated machine, then garments should be dried.

2.Design preparation

Before printing, we must check the digital design file’s compatibility with the printer. It is very practical to test on some pieces of garment to ensure the output is the same as expected.

3.Inkjet printing

When everything is ready, it’s time to place the garment in the direct-to-garment printer and begin the digital printing. Notably, all garments, especially dark color ones, need to have a white under base applied first for enhancing the vibrancy of the final print.

Furthermore, you should make sure that garment is loaded correctly and is as flat as possible. One wrinkle will ruin all. Once loaded, printheads spray ink or dye with tiny droplets through the precise control of a computer and you just wait to witness the miracle of designs!

4.Post-treatment

When it comes to pigment inks, post-treatment is also easy. Drying is the only thing, used for curing the ink.

Benefits & applications of DTG printing

DTG printing offers high-resolution prints with vibrant colors that are long-lasting. You can create impressive designs and amazing details on garments using any color that you want, as long as you have the right treatment liquid and ink colors. The printer uses tiny droplets of ink to create the image on the textile, and by varying the amount and placement of each color, the printer can create millions of different color combinations.

It also allows for quick turnaround times, as the printing process is automated and requires no setup time. Many experts believe that direct-to-garment printing is ideal for small runs and one-off designs, as it is cost-effective and efficient. That is why it adapts well to the fast fashion industry which needs on-demand manufacturing and refined inventory management. Besides, DTG is very eco-friendly for it produces little pollutants, toxic fumes, or waste effluent.

Since direct-to-garment printers use water-based ink, you can get the best results with natural fabrics. These textiles are the most suitable for DTG:

--Cotton

--Ring-spun cotton

--Organic cotton

Polo shirts and t-shirts are among the most popular products produced by DTG. They’re both staples of the wardrobe, so you’ll never run the risk of them being out of date.

Concerning its drawbacks, DTG printing is generally more expensive and slower than other methods. Related equipment, ink & other consumables, as well as maintenance can be costly, which may improve in the future, especially in the respect of inks.

Some people wonder if DTG can print on polyester, the answer is “no”. Direct-to-garment printing is not effective when printing on polyester, which has turned out to be a huge threshold for the sports industry.

DTG printer buying guide

Most DTG printer users provide clients with customized textiles. As mentioned above, direct-to-garment printing is relatively cost-efficient and quick in small to medium-sized job sizes.

Below is the list of factors that you need to consider before buying DTG printers.

1.Printing volume

2.Printing speed

3.Printer quality & cost

4.Warranty & maintenance requirements

Printing volume is the starting point of your thinking. You should consider it according to your order quantity or potential business. Based on this plus printing speed, you would work out a budget including expenses. Notably, sometimes you might have to prioritize between speed and quality based on daily production. Please remember to choose carefully!

If daily printing demand of your business is no more than one or two hundred, small printers may be enough. However, if your orders are in large quantities and you use them for factories, high-volume DTG printers are absolutely essential.

In general, a direct-to-garment printer is expected to cost more than a standard printer. However, your personalized products often offer a premium for their unique designs or colors. You need to make a balance between DTG printers with excellent performance and high purchasing costs through precision calculation.

As for the quality, print head performance is a crucial part. You must know about the smallest droplet size, the printheads can produce, and the maximum DPI. Color accuracy is also an important element to consider. Only in this way, will you be sure to provide satisfying products for customers.

Before buying these cheap machines, be sure to ask questions like: “How long have you been in business? What is the guarantee?” That’s quite useful. Please Ask for the DTG printer’s manual and have the maintenance process — especially its costs — fully explained. Potential maintenance cost is also a part of the purchasing cost.

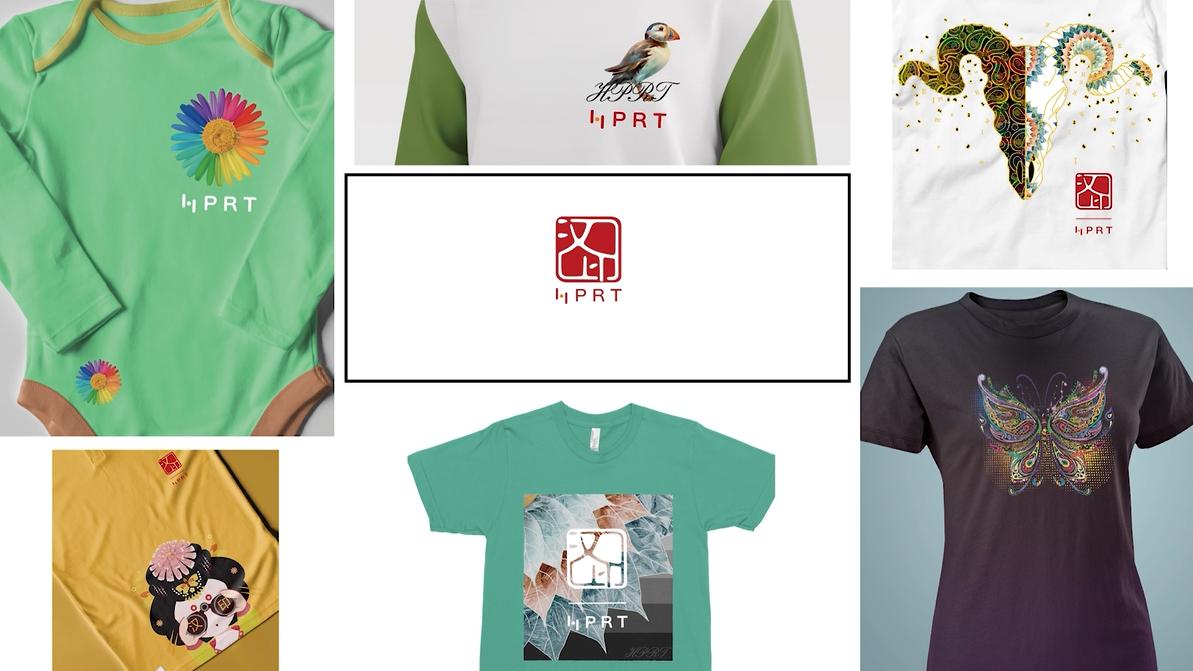

Here we will introduce you to our DA067D DTG printer, which is completely self-developed by HPRT.

The DA067D DTG printer offers an all-in-one garment printing model to make printing simple and interesting. It delivers high-speed printing, up to 160 pieces per hour. Though it, any unique colors and amazing patterns can be accessible. Moreover, the DA067D DTG printer develops a creative ink supply system and inks can be added during operation, highly improving production efficiency.

Conclusion

With the increasing demand for unique and personalized products, direct-to-garment printing offers a flexible and efficient way to produce custom designs at a reasonable cost. As technology advances, DTG printing is becoming more accessible and affordable for small businesses and individuals. It is also expected to become more environmentally friendly as more eco-friendly ink options become available. Let’s wait and see how direct-to-garment printing will shape the textile industry and bring surprise us.