Heating Up Sustainability: The Power of Thermal Label Printers in Eco-friendly Packaging

The global push for eco-friendly practices has businesses and consumers alike seeking ways to reduce their environmental impact. One area where sustainable solutions are gaining traction is packaging, where thermal label printers have emerged as an integral player. In this article, we’ll explore the transformative role of thermal label printers in sustainable packaging, highlighting their environmental benefits, innovative features, and a few real-life examples that bring their power to life.

Eco-friendly Label Materials

The green credentials of thermal label printers begin with the label materials themselves. Recyclable and compostable materials, such as paper made from responsibly-sourced fibers or PLA (polylactic acid), are becoming more prevalent. Innovations in eco-friendly label materials have led to the development of thinner, lighter, and more sustainable options that significantly reduce environmental impact.

For example, companies like UPM Raflatac offer a range of eco-friendly label materials, including those made from post-consumer waste, FSC-certified paper, and renewable sources, meeting various sustainability standards.

Energy Efficiency of Thermal Label Printers

When it comes to energy usage, thermal label printers have the edge over traditional printing methods. They consume less power, thanks to their efficient heating elements, and many modern models feature standby mode and power-saving settings. This reduced energy consumption not only lowers a business’s carbon footprint but also results in cost savings.

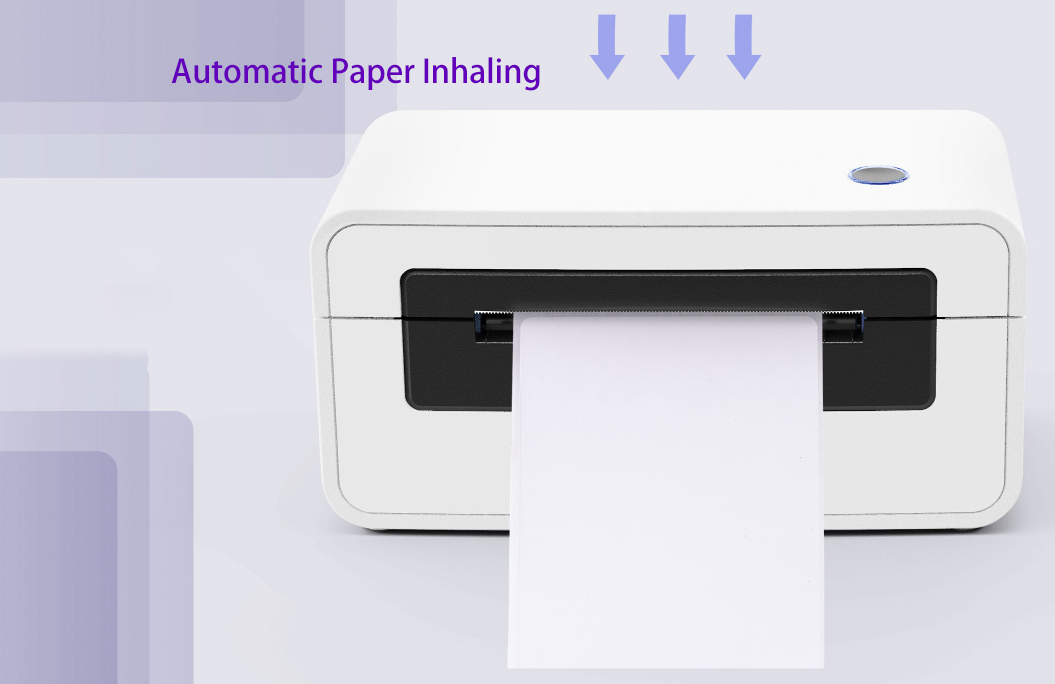

In addition, the intelligent design of some label printers is also helping to promote "green" actions, such as the HPRT N41 energy-efficient shipping label printer. Its automatic paper inhaling and rollback function ensures that the first label is never wasted, and its automatic label detection function ensures that each label is in the correct position, avoiding material waste caused by printing errors.

Reducing Waste with Thermal Label Printers

Thermal label printers contribute to waste reduction in several ways. First, they require minimal consumables, such as labels and ribbons. Second, linerless label options eliminate the need for label backing, further reducing waste. Finally, precision cutting technology ensures optimal use of label materials, minimizing offcuts.

A prime example of waste reduction is the use of linerless labels in the retail sector. Stores like UK-based supermarket chain Tesco have adopted linerless labels for their in-house bakery products, eliminating millions of meters of backing paper waste annually.

Customization and Flexibility

On-demand label printing capabilities are another strength of thermal label printers. Businesses can print labels as needed, reducing overproduction and material waste. Furthermore, variable data printing allows for easy customization, such as printing labels with unique barcodes, serial numbers, or product information.

Barcoding and Traceability

Thermal label printers’ ability to produce high-quality barcodes and QR codes enhances traceability throughout the supply chain. Accurate tracking and tracing of products contribute to improved product lifecycle management and a more efficient supply chain, ultimately reducing waste and promoting sustainability.

Cost Savings through Sustainability

By implementing thermal label printers into their operations, businesses can achieve significant cost savings. Lower material costs, reduced energy consumption, and improved operational efficiency all contribute to a healthier bottom line. Moreover, embracing sustainable practices can enhance a company’s reputation, attracting environmentally conscious consumers and partners.

For example, the Danish organic food brand, Naturli’ Foods, which uses thermal label printers with eco-friendly labels for their plant-based products. By doing so, they minimize waste and ensure their packaging aligns with their commitment to sustainability.

Future Developments in Thermal Label Printing

As technology continues to evolve, we can expect further advancements in thermal label printing. Emerging technologies, such as the Internet of Things (IoT) and machine learning, have the potential to enhance printer performance and efficiency, while novel materials and applications could further reduce environmental impact.

Conclusion

Thermal label printers are reshaping the world of sustainable packaging, offering eco-friendly solutions that reduce waste, improve efficiency, and promote environmental responsibility. By embracing these powerful tools, businesses can move towards a greener future and make a lasting impact on our planet.