How RFID Technology is Revolutionizing the Apparel Industry

Gone are the days when high-end apparel stores relied on traditional barcode scannersfor checkout. Now, thanks to RFID technology, your selected items are automatically recognized and billed as soon as you place them in the checkout area. This innovation eliminates the hassles associated with failed scans or damaged barcodes. The application of RFID technology in retail has not only streamlined the checkout process but has also had a profound impact on the entire apparel retail sector.

Introduction to RFID Technology

RFID, or Radio-Frequency Identification, is a technology that uses radio waves to identify items. Unlike manual scanning, RFID technology allows for automatic identification of items tagged with RFID labels. These RFID clothing tags are usually placed on the garment’s label or sewn into areas like cuffs, collars, and hems.

RFID Clothing Tags typically consist of:

1. Chip: An electronic component that stores information about the garment, such as style, size, and color.

2. Antenna: Responsible for transmitting and receiving radio signals, much like a radio antenna.

3. Substrate: The tag’s material, often made of durable fabrics like nylon to withstand daily wear and tear.

RFID tags on clothes enable touchless information reading, significantly enhancing the efficiency of inventory checks and the checkout process. These tags can store a vast amount of data and support information rewriting, catering to the apparel stores’ demands for effective merchandise information management. Currently, several major brands in the fashion industry, including H&M, Nike, and Uniqlo, have integrated these RFID labels into their operations.

Before hitting the stores, these garments are tagged and encoded with RFID labels at the factory level. For instance, Nike started using RFID tags in 2017 to enhance production management and traceability.

The HPRT Bingo 4-Inch Industrial RFID Printeris equipped with cutting-edge chips, boasting expansive storage capabilities and precise antenna positioning features.

It is not just adept at handling large-scale barcode label printing tasks but is also proficient in reading and writing UHF RFID tags, encompassing those used for apparel and fixed assets. As a result, this RFID label printer is widely utilized across a range of sectors, including apparel, logistics, manufacturing, and healthcare.

Additionally, the Bingo offers automatic label position calibration, ensuring precision in printing. Its user-friendly design, featuring a 3.5-inch color touchscreen and intuitive buttons, makes operations seamless. Moreover, with its USB HOST support, it facilitates convenient offline printing.

Rich Applications of RFID Technology in Clothing Stores

1. Quick Self-Checkout with RFID Technology

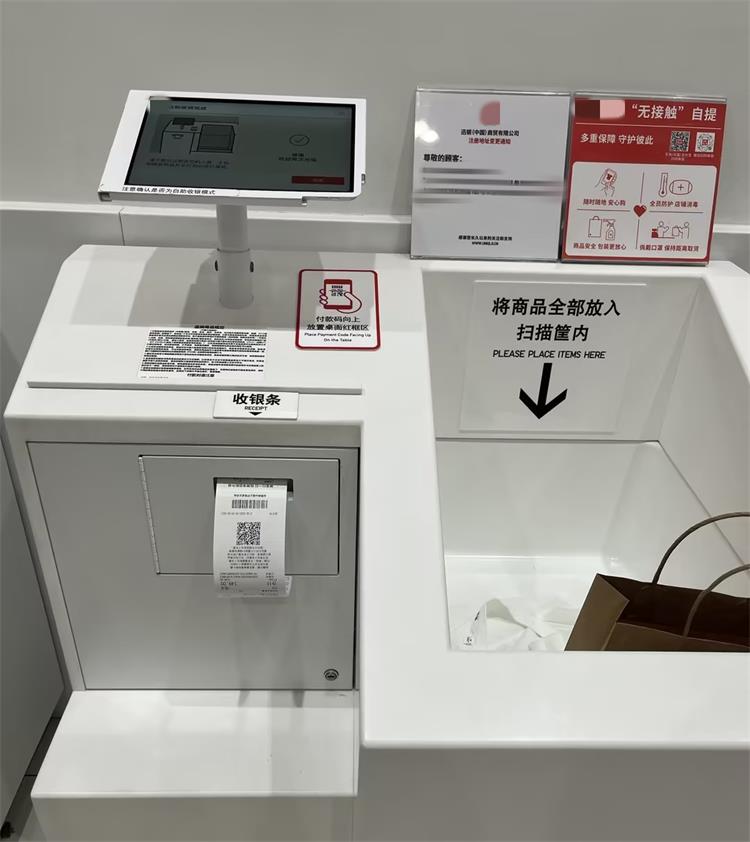

RFID technology has revolutionized the checkout process in clothing stores, offering distinct advantages. For instance, Decathlon has already incorporated RFID-enabled self-checkout counters in some of its stores, significantly boosting checkout efficiency and enhancing the overall customer experience. Shoppers simply need to take their selected items out of the shopping basket and place them on the self-checkout counter. The RFID technology swiftly recognizes each product, completing the transaction in mere seconds.

● Increased Checkout Speed: The RFID self-checkout system can scan multiple items simultaneously once they are placed on the counter. This is a vast improvement over traditional barcode scanning, drastically reducing the time spent at the checkout and accelerating the customer flow.

● Enhanced Customer Experience: Thanks to the speed of the RFID self-checkout, customers no longer face the inconvenience of waiting in long queues. This not only speeds up the shopping journey but also elevates the overall shopping experience for the customer.

● Reduced Labor Costs: The introduction of RFID self-checkout counters has diminished the need for manual checkouts, subsequently leading to a reduction in labor costs. This automated service allows store staff to focus more on offering value-added services, such as assisting customers with inquiries and managing product displays.

2. Efficient Inventory Management with RFID Technology

Traditional inventory checks in large stores often involve the manual scanning of each product’s barcode, making it a tedious and time-consuming task. With RFID technology in retail, inventory checks can be swiftly conducted using PDA devices. Given that RFID tags are resistant to damage and can be recognized from a distance, this greatly enhances the accuracy and efficiency of inventory checks.

Notably, RFID technology can identify not just individual items but also items that are stacked or hard to reach, proving invaluable for high-shelf inventory or mixed product checks.

3. Rapid Item Location with RFID Technology

RFID tags on clothes utilize radio frequency signals for both transmission and reception, allowing for the accurate pinpointing of product locations. This technology aids store staff in quickly identifying specific items on the shelves, an advantage that becomes particularly pronounced during busy shopping periods or when streamlining inventory management.

The underlying mechanism involves the RFID tags emitting these signals, which are subsequently captured and interpreted by shelf-mounted readers to ascertain the tag’s exact position.

Several H&M outlets have integrated this RFID technology into their retail operations, equipping their premises with readers that continuously update the real-time location of products. As customers browse and search for specific items, store associates can employ handheld devices to scan the RFID garment tags, immediately presenting the item’s location on a display. This approach not only enhances the productivity of the staff but also significantly improves the shopping experience for customers.

4. Smart Sales Management with RFID Technology

Specifically for best-selling items, RFID technology has transformed the traditional inventory and restocking management methods. For instance, Uniqlo in Japan has utilized RFID technology for automated restocking in some of its stores. The RFID system in Uniqlo can automatically trigger restocking requests based on real-time inventory conditions and sales traffic, significantly enhancing stock turnover efficiency.

5. Anti-Theft Measures with RFID Technology

RFID tags also play a pivotal role in theft prevention. When an unpaid item, equipped with RFID clothing tags, exits the store, the RFID system instantly activates an alarm, offering an added layer of security. This mechanism not only minimizes theft risks but also strengthens the management capabilities for high-value items like branded clothing or accessories.

The application of RFID technology in the apparel industry is widely acknowledged, especially as costs continue to decrease. Brands like Uniqlo have successfully leveraged RFID technology for inventory management, significantly improving stock turnover rates. With the ongoing pursuit of efficiency and cost control, RFID technology will undoubtedly continue to drive technological innovation and business model transformation in the apparel industry.