Industrial Fabric Printer: Types, Features, Applications & Future Prospects

In recent years, the textile industry has experienced a shift towards digital printing technology, and the industrial fabric printer has been at the forefront of this revolution. These specialized printers can produce high-quality, large-scale prints on a variety of fabrics. In this article, we will explore the definition, different types, features, and applications of industrial fabric printers.

What is an industrial fabric printer?

Broadly speaking, an industrial fabric printer is a specialized printing machine used for printing on a wide range of fabrics, such as cotton, polyester, silk, and others. Based on this definition, industrial fabric printers have many types, such as traditional screen printers and dye-sublimation printers.

Actually, the industrial fabric printers we often talk about are with digital attributes. Now, the textile industry is advancing at a rapid pace and an industrial digital fabric printer is one such innovation that has revolutionized the printing of fabrics.

Here we focus on industrial fabric printers with digital attributes. These fabric printers use a series of inkjet nozzles to print high-quality images or designs onto fabric through digital technology. They are typically large-scale machines that are designed to handle large volumes of fabric. The ink used in these printers is specially formulated to adhere to the fabric, resulting in bright and vivid colors. The printers are controlled by computer software, allowing for precise control over the printing process.

Industrial fabric printers vs non-industrial fabric printers

The marked difference between an industrial fabric printer and a non-industrial fabric printer lies in their designs and capabilities. Industrial fabric printers are designed to handle large-scale printing projects, while non-industrial fabric printers are typically used for small-scale printing projects.

In general, industrial fabric printers are built with heavy-duty components that can handle the demands of high-volume printing. They are capable of printing on a wide range of fabrics, including thick and heavy fabrics. They also have larger printing beds, allowing for the printing of larger designs and patterns.

Non-industrial fabric printers, on the other hand, are designed for smaller projects and are typically used by individuals or small businesses. They are not built for heavy use and may not be capable of printing on all types of fabrics. Non-industrial fabric printers also have smaller printing beds, which limits the size of designs that can be printed.

Besides, industrial textile printers are typically much more expensive than non-industrial printers due to their advanced features and capabilities. They are also built to last longer and can withstand the demands of heavy use.

Types of Industrial Fabric Printers

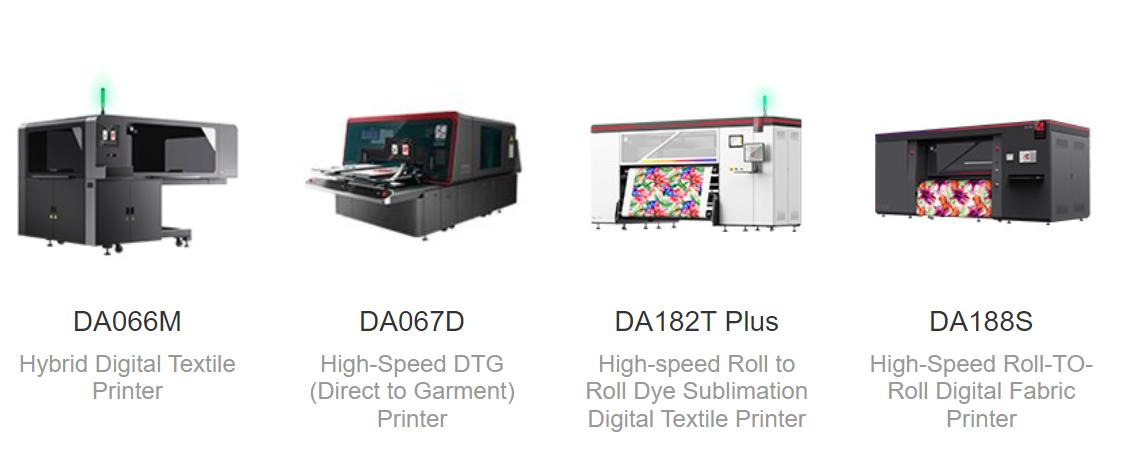

There are different types of industrial digital fabric printers available in the market, each with its unique features and capabilities. The most common types of industrial fabric printers are:

DirectDigitalTextile Printers:

These printers are designed to print directly on the fabric without the need for any transfer paper. The printer transfers ink directly to fabric or directly to garments with the help of ink-jet technology. They apply to a wide range of fabrics and produce vibrant and long-lasting prints since inks penetrate the fabric fibers.

Dye-Sublimation Printers:

These printers use a special type of ink that is heated to a high temperature and turns into a gas. The gas then penetrates the fabric and solidifies it to create a permanent and vibrant print. Dye-sublimation printers are widely used for printing on polyester and other synthetic fabrics.

Click here for a detailed description of the types of industrial fabric printers.

Features of Industrial Fabric Printers

Industrial digital printers come with several features that make them suitable for different types of fabrics and printing requirements. Some of the key features of industrial fabric printers are:

Built for mass production:

Unlike commercial-grade digital fabric printers, industrial-grade ones regular can handle heavy-duty textile, and garment printing tasks. They are a perfect solution for large textile printing or clothes manufacturers.

High-Resolution printing:

Industrial digital printers are capable of producing high-quality prints with sharp and clear details. They use advanced print heads and ink technology to achieve high resolution.

More colors & patterns:

Industrial textile printers can print with multiple colors of ink, allowing for the creation of vibrant and colorful designs. Some printers can print with up to 12 different ink colors. They provide endless colors and natural tonal transitions between the colors that conventional screen printing cannot offer.

Faster turnaround time:

Industrial textile printers’ digital attributes allow for faster turnaround times, reducing the time and labor required to produce each screen which is required by screen printing. It’s such an exciting thing in the fast fashion garment industry that these printers can provide qualified products in a short time in an attempt to catch up with the fashions.

Computer controlling:

It’s labor-saving to operate these fabric printers as they are controlled by computers. Most of them are equipped with smart systems such as automatic print head cleaning and automatic moisturizing, thus simplifying operations, improving work efficiency and reducing labor costs. Furthermore, it provides you with great flexibility and the possibility of changing and modifying designs before mass production.

Applications of Industrial Fabric Printers

Industrial digital printers are used in a variety of industries for the production of different types of fabrics. Some of the common applications of industrial textile printers are:

Fashion industry:

Industrial fabric printers are widely used in the fashion industry for the production of designer clothing, accessories, and footwear. They are used to print patterns, designs, and images on different types of fabrics, such as silk, cotton, and denim.

Home textiles:

Industrial digital printers promote prosperity in the home textile industry with their distinct features. They offer lots of customized products such as curtains, bedspreads, and upholstery. And they can also print a wide range of designs, from floral patterns to geometric shapes, on different types of fabrics.

Advertising industry:

Industrial textile printers are used for the production of banners, billboards, and flags. They are capable of printing large-scale designs on different types of fabrics, such as vinyl and mesh.

Future Prospects of Industrial Fabric Printers

The prospects of industrial fabric printers are promising, as they continue to evolve with new technologies and advancements. Industrial fabric printers could potentially be used for the 3D printing of fabrics. This would enable the production of intricate and complex designs that cannot be achieved with traditional printing methods. Sustainability is also getting more attention as various eco-friendly inks and fabrics are being developed at present.

HPRT supplies industrial digital fabric printers to global customers. Contact us to learn more about the products or get a quote.