Powerful Thermal Transfer Label Printers - Printing High-Resolution Labels

In a modern society that emphasizes brand marketing and packaging design, labels have become an important component of almost every product. They serve various purposes, including providing product information, usage instructions, and conveying brand identity. However, what happens when a label is blurry, difficult to read, or cannot be scanned? This not only causes inventory confusion and decreased sales but can also pose safety hazards. Fortunately, with high-resolution labels generated by thermal transfer label printers, we can effectively avoid these problems. In this article, we will uncover the secrets of high-resolution labels with thermal transfer label printers, covering the basics of thermal transfer printing, label resolution, and the factors that affect label quality.

The Basics of Thermal Transfer Printing

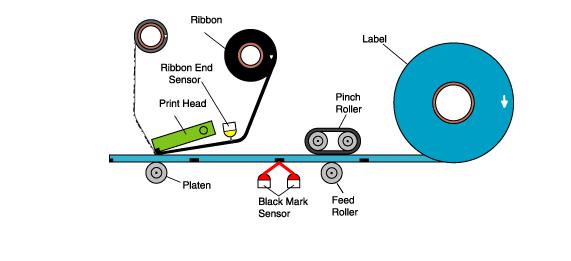

To understand the secrets of high-resolution labels, it’s crucial to understand the basics of thermal transfer printing. This method employs a thermal print head that applies heat to a carbon ribbon, which can be made of wax, resin, or a combination of both. The ink from the ribbon then melts onto the label’s surface, resulting in a high-quality, durable image.

Understanding Printing Resolution

Printing resolution is the sharpness and clarity of an image or text on a label, measured in DPI (dots per inch) or PPI (pixels per inch). The higher the DPI or PPI, the better the printing resolution. DPI and PPI are often used interchangeably, but they are different. DPI refers to the number of dots per inch printed on the label, while PPI refers to the number of pixels per inch that the image being printed contains.

Choose a printer with the right resolution is essential to ensure the printed label is clear and legible. When designing a label, it’s vital to consider the label size, the size of the text or image, and the required DPI or PPI.

Factors that Affect Label Printing Quality

Several factors can affect label printing quality, including label material, print speed, printer resolution, and the ribbon selected.

Choosing the right label material

Choosing the right label material is essential to ensure the label is durable and can withstand various environmental factors such as moisture, temperature, and abrasion.

Coated and uncoated thermal transfer labels are two commonly used label materials in thermal transfer printing. Coated labels have a layer of material that allows ink to adhere better to the label’s surface. When high-resolution images are needed, coated labels should be considered. They are commonly used in industries such as healthcare, logistics, and manufacturing where labels need to withstand harsh environmental conditions.

Coated labels are also suitable for printing high-resolution barcodes to ensure accurate and fast scanning. On the other hand, uncoated labels are suitable for printing simple, text-based labels that do not require high resolution.

Print speed also affects label printing quality. Printing too quickly can result in blurred images or text, while printing too slowly can cause ribbon wrinkles, resulting in poor print quality.

The printer resolution is another crucial factor in label quality. The higher the printer resolution, the better the label quality. A printer with a higher resolution can produce more detailed images and text, resulting in a high-quality label.

The ribbon selected also plays a significant role in label quality. Using a high-quality ribbon can result in a label with sharper images and text, better durability, and resistance to harsh environmental conditions.

Printing High-Resolution Labels with Thermal Transfer Label Printers

Many of the thermal labels we see in our daily lives are printed directly from direct thermal label printers, such as the shipping labels, which have a resolution of mostly 203 DPI. On the other hand, the common resolution of thermal transfer label printers is 300 DPI, which is suitable for printing high-quality and high-resolution labels with clear images and text. Some thermal transfer printers can even generate labels with resolutions of 600 DPI or 1200 DPI, which are far beyond the reach of direct thermal label printers.

What are the reasons behind this?

Firstly, it’s due to the printing technology used. Specifically, thermal transfer printers use a ribbon to transfer ink onto the label, while direct thermal printers use a thermal coating to create an image by reacting to the heat from the print head. This limits the achievable resolution because such printing processes are less precise compared to thermal transfer printing.

Moreover, thermal transfer printers can use a higher ink density ribbon to produce more detailed images. Compared to the thermal coating used in direct thermal printing, carbon ribbon can accommodate more ink, resulting in even higher image resolution.

In addition, compared to direct thermal printing, labels printed by thermal transfer printers have better durability, specifically they are more resistant to moisture, heat, and UV radiation. As we all know, labels like shipping labels or receipts generated by direct thermal printing fade over time and the contents become difficult to identify.

Another advantage of thermal transfer printing is that it can print on various label materials. Thermal transfer label printers can print on synthetic materials such as polyester, vinyl, and polypropylene, which are ideal choices for harsh environments. Direct thermal printing is basically limited to paper labels and is not suitable for damp or humid environments.

Advantages of High-Resolution Labels

High-resolution printed labels offer several advantages over standard printed labels, including improved readability and legibility, increased durability and resistance, and enhanced branding and aesthetics.

a. Improved Readability and Legibility

High-resolution labels are easier to read and understand, even from a distance. The sharp, clear images and text make it easier to identify the product, read instructions, and understand warnings and precautions.

b. Increased Durability and Resistance

High-resolution labels are more durable and resistant to harsh environmental conditions such as moisture, temperature, and abrasion. This makes them ideal for use in industries such as healthcare, manufacturing, and logistics, where labels need to withstand a variety of conditions.

c. Enhanced Branding and Aesthetics

High-resolution labels can enhance the product’s branding and aesthetics, making it stand out on the shelf. They can be customized with colors, images, and logos to create a unique and attractive label that appeals to consumers.

Final Thoughts

Thermal transfer label printers are the go-to technology for producing high-resolution labels. The use of thermal transfer label printing technology and high-quality label materials can result in labels that are sharp, clear, and able to withstand harsh environmental conditions. HPRT offers a wide range of thermal transfer printers for barcodes and labels printing. Contact us to get a catalogue.