Understanding FDM 3D Printer Resolution: From Basics to Improvements

In the rapidly evolving landscape of 3D printing, FDM (Fused Deposition Modeling) technology has made significant strides. From its early days, where print accuracy hovered around 0.5mm, we’ve seen a dramatic leap forward. Today, top-tier industrial-grade FDM printers, can achieve a staggering resolution of 0.05mm. This tenfold increase in precision has opened up new possibilities and raised new questions. What exactly is the resolution of FDM 3D printing? And what does this mean for the future of 3D printing? This article delves into these questions, shedding light on the critical concept of FDM 3D printer resolution.

Definition of FDM 3D Printer Resolution

FDM 3D printers have gained popularity among 3D enthusiasts and craft hobbyists due to their accessible entry-level and budget-friendly prices. A frequently asked question when purchasing a 3D printer is, "What is the resolution of this printer?" The 3D printer resolution is a crucial parameter as it directly affects the quality of the printed object.

Simply put, 3D printer resolution refers to the level of detail a printer can achieve, and in FDM 3D printing, it refers to the smallest movement the printer can make in the X, Y, and Z directions. It’s usually measured in microns - the smaller the number, the higher the resolution, and the finer the details that can be printed.

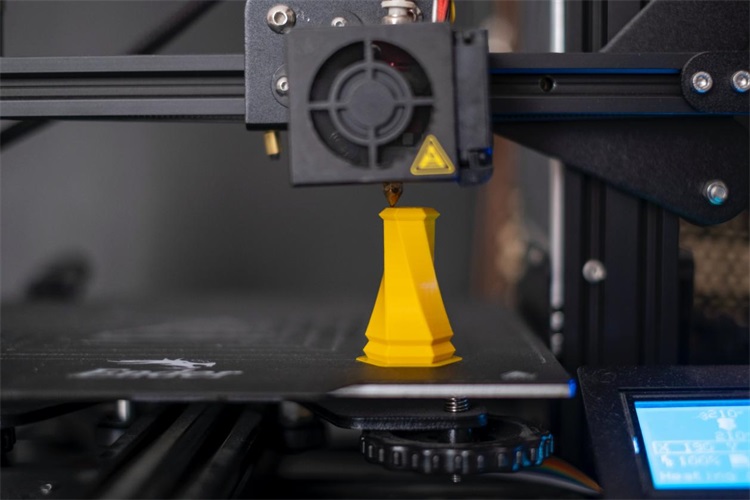

It’s essential to understand the working principle of the high-resolution FDM 3D printer at this point. Initially, the FDM 3D printer feeds thermoplastic material from a filament reel into a heated module and nozzle, melting the material. The printer’s computer control system then dictates the nozzle to move along specific paths on the X and Y axes (or the horizontal plane) based on the pre-set 3D model design, extruding the molten material.

This process resembles piping cream, accumulating layer by layer on the print bed. After completing a layer, the bed shifts a pre-defined distance along the Z-axis (or vertically), making room for the next layer. The nozzle then begins extruding the material for the next layer, which adheres tightly to the surface of the preceding layer. In this manner, the printer can construct intricate three-dimensional models layer by layer.

● Horizontal Resolution

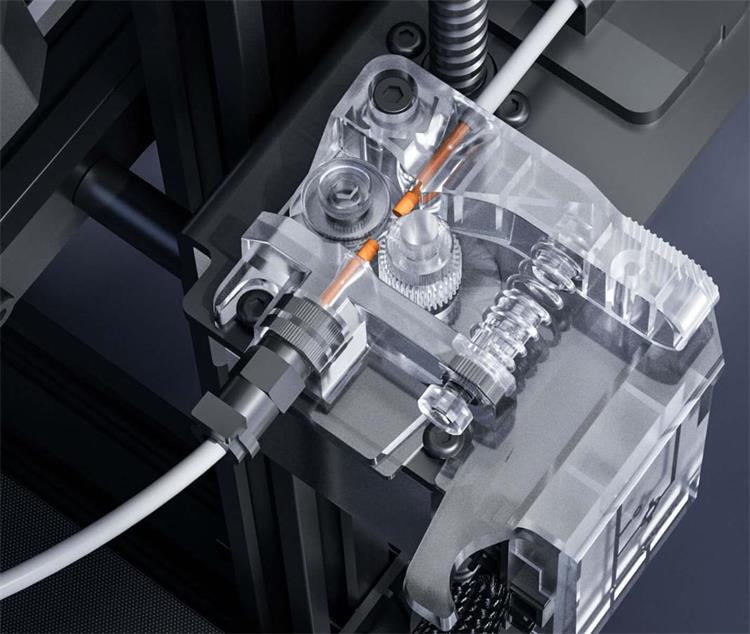

The horizontal resolution in FDM 3D printing is largely determined by the precision of the stepper motor, which controls how minutely the printhead (or the bed) can move. The size or fineness of the teeth on the X/Y belt can also influence the resolution, although this effect is often minimal as long as the teeth are ideally proportioned for the gear attached to the stepper motor.

The XY resolution is particularly important when printing parts that are meant to fit together. A high XY resolution ensures that the parts are printed with the exact dimensions specified in the 3D model, allowing them to fit together perfectly.

●Vertical Resolution

Vertical resolution, often referred to as layer height, is primarily influenced by the nozzle diameter and the precision of the stepper motor that controls the movement of the build platform (or the printhead) along the Z-axis.

Nozzle Diameter:

The nozzle is the part of the 3D printer that extrudes the molten filament onto the build platform. The diameter of the nozzle determines the thickness of the filament that it extrudes. A smaller nozzle diameter will extrude a thinner line of filament, which allows for thinner layers and therefore a smaller layer height. Conversely, a larger nozzle diameter will extrude a thicker line of filament, resulting in thicker layers and a larger layer height.

Precision of the Stepper Motor:

The stepper motor is responsible for moving the build platform (or the printhead) up and down along the Z-axis. The precision of the stepper motor determines how small of a step it can take, which in turn determines the minimum layer height that the printer can achieve. A stepper motor with higher precision can take smaller steps, allowing for smaller layer heights.

A smaller layer height (higher resolution) will result in smoother surfaces and more detailed features, as the layers are thinner and therefore less visible. This is particularly important when printing objects with curved or sloping surfaces, as a smaller layer height will more accurately reproduce these shapes.

However, a smaller layer height also means that more layers are needed to print the object, which can significantly increase the print time. Therefore, when choosing the layer height, it’s important to strike a balance between print quality and print speed.

FDM 3D printers can indeed be divided into industrial and desktop categories, each with their own typical uses and resolution capabilities.

In the dynamic world of 3D printing, FDM 3D printers fall primarily into two categories: industrial-grade and desktop-grade.

The industrial-grade printers, utilized in sectors such as automotive, aerospace, and manufacturing, often use high-temperature-resistant filaments like PEEK. These printers are tailored for crafting large components, boasting a 3D printer resolution that spans from 50 to 250 micrometers.

On the other hand, desktop-grade printers cater more to individual enthusiasts, educational entities, and small enterprises. They typically print smaller to medium-sized objects, with a print resolution ranging from 100 to 300 micrometers.

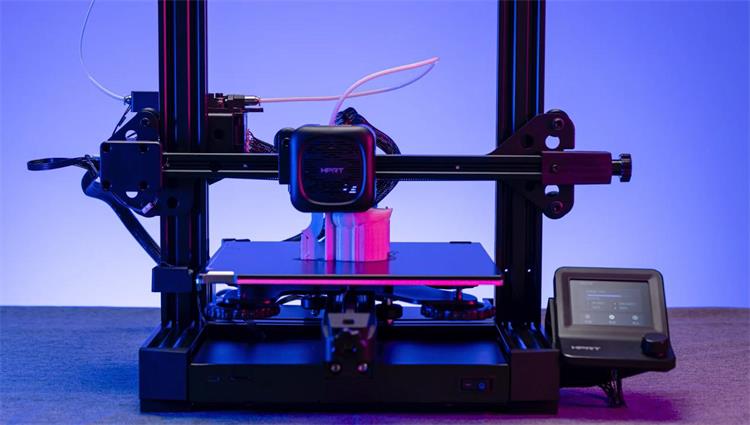

Consider the HPRT F210 as a prime example. This entry-level 3D printer is ideal for both educational environments and crafting aficionados. Once users input their 3D model files, this high-resolution FDM 3D printer seamlessly tackles a myriad of 3D printing tasks — from crafting personalized artworks to producing diverse models, teaching tools, and bespoke parts.

Sporting an all-metal design paired with a steadfast gantry structure, the HPRT F210 guarantees a 3D print resolution of up to 200 micrometers, meeting an extensive array of 3D printing demands.

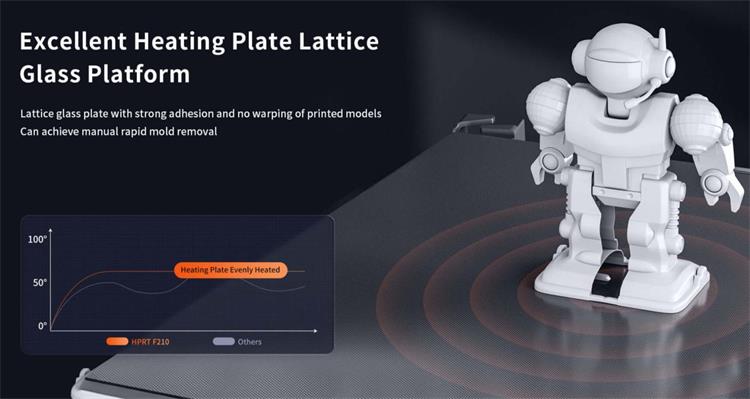

In terms of usability, its intuitive interface, showcased on a modern UI display, makes navigation and setting adjustments a breeze. The device’s lattice glass plate assures robust adhesion, reducing the chances of print warping and facilitating quick manual model extraction.

When juxtaposed with standard models on the market, the enhanced F210 version stands out with its intelligent protection system. It boasts features like filament outage detection and power outage recovery, effectively curtailing time losses due to material deficits and eliminating idle runs.

With its compatibility for 1.75mm diameter filaments such as PLA, TEPG, TPU, and others, the F210 offers diverse application potential. DIY enthusiasts can harness its capabilities for creating everyday items, such as bottle caps or phone holders. In the educational realm, the printer becomes an interactive tool, allowing instructors and pupils to transform theoretical concepts into tangible, hands-on models, making learning more interactive and fostering creativity among students.

How to Improve the FDM 3D Printer Resolution

Improving 3D printer resolution can be achieved by fine-tuning the printer settings, using a finer nozzle, slowing down the print speed, and ensuring the printer is well-calibrated. It’s also important to use high-quality printing material.

●Printer Precision: The inherent precision of the 3D printer plays a crucial role. Factors such as the manufacturing and assembly accuracy of the 3D printer, as well as operational vibrations, can all impact the final printing accuracy. The printer’s precision is largely determined by the accuracy and reliability of its mechanical components, especially those responsible for movement.

●Layer Thickness: Layer thickness, or layer height, is another significant aspect. Each layer possesses a certain thickness, which can result in visible step lines on the surface of the printed object.

These are more noticeable with larger layer heights and directly affect the dimensional accuracy and surface roughness of the printed object. While it’s impossible to completely eliminate these step lines in FDM printing, their visibility can be reduced by setting a smaller layer thickness.

●Nozzle Characteristics: Both the diameter and temperature of the nozzle play a crucial role in the printing process. The diameter of the nozzle determines the width of the extruded filament, which can impact the precision of the print.

The layer height setting also affects the surface roughness of the print: a larger diameter nozzle results in thicker layer heights, faster printing speeds, but rougher prints. Conversely, a smaller diameter nozzle can produce finer prints, albeit at a slower speed.

The temperature of the nozzle influences the adhesive properties, stacking performance, and flow rate of the filament. It’s important to ensure the nozzle temperature is not too low or too high. A low temperature increases the material’s viscosity, slowing down the extrusion speed. Conversely, a high temperature makes the material more liquid-like, reducing viscosity and increasing flow, which can lead to imprecise extrusion.

By delving into the factors that affect printing accuracy and making the necessary adjustments, one can significantly enhance the quality of prints. This improvement is evident whether the printing is used for educational purposes, industrial production, or just regular DIY projects. However, given the intricate nature of 3D printing — which encompasses various factors and parameters — refining the print accuracy typically requires a mix of practical experience and learning through trial and error.

In light of this, we recommend the HPRT F210 3D printer. Transform this summer into a season overflowing with innovation and creativity. With your commitment and determination, you can achieve significant progress in the world of 3D printing. As a trusted printer equipment manufacturer, HPRT is deepening its engagement in the 3D printing sector, broadening its product offerings and providing both OEM and ODM services. Should you be interested in our 3D printers, we welcome you to contact us.