What You Need to Know About Waterproof Label Printers

Imagine you’re running a business that sells outdoor equipment, and your customers expect the product labels to withstand harsh weather conditions without fading or deteriorating. Or perhaps you manage a food and beverage company where your product labels must endure cold storage and moisture exposure. In both scenarios, a waterproof label printer is crucial for producing durable, water-resistant labels that meet industry standards and customer expectations. This article aims to provide a comprehensive understanding of waterproof label printers, their importance, types, and the process of printing waterproof labels.

Why Do We Need Waterproof Label Printers?

Waterproof labels are essential in industries where products or packaging may be exposed to moisture, water, or other harsh conditions, such as food and beverage, cosmetics, chemicals, and outdoor equipment.

For instance, labels on products like shampoo and conditioner often have to withstand the humid environment of a bathroom, while food items like ice cream and beverages often need to be stored in the freezer. These labels need to withstand humidity, condensation, and water exposure without smudging, fading, or deteriorating. Waterproof label printers ensure that the printed labels remain legible and intact, maintaining product safety and compliance with industry regulations.

Main Types of Waterproof Label Printers

Based on the printing principle, waterproof label printers can be divided into three major categories: thermal label printers, laser printers, and inkjet printers, each with its features and applicable industries.

a) Thermal Label Printer:

These printers use direct thermal or thermal transfer printing technology to produce waterproof labels. Direct thermal printers use heat-sensitive label material, while thermal transfer printers use a thermal ribbon to transfer ink onto the label material. Both types are ideal for applications in industries like logistics, retail, outdoor sports, and healthcare.

Thermal label printers are often used for temporary labels, such as courier bills and cash receipts, but the labels they print can also have waterproof features under specific conditions. Thermal transfer label printers can achieve waterproof effects by choosing the right ribbons and label materials.

b) Laser Printer:

Laser printers use toner and heat to fuse the print onto waterproof label material. They are suitable for high-quality, high-volume printing and are commonly used in office environments, manufacturing, and pharmaceutical industries.

c) Inkjet Printer:

Inkjet printers use water-resistant, pigment-based inks to print onto waterproof label materials. They are suitable for producing full-color, high-resolution labels and are often used in the food and beverage, cosmetics, and chemical industries.

Generally speaking, laser and inkjet printers are not suitable for printing small labels. For roll-type labels, thermal label printers are more suitable.

In practical applications, thermal label printers are the primary choice for waterproof label printing due to their durability, efficiency, and cost-effectiveness. They are less prone to smudging or fading, as they don’t rely on ink that can run or bleed when exposed to water. Additionally, they offer faster print speeds, and lower maintenance costs compared to inkjet or laser printers.

How to Print Waterproof Labels

Next, we will present to you how to print waterproof labels, just follow these steps:

a) Select appropriate waterproof label material:

Choose a label material that is specifically designed for waterproof applications and usage scenario characteristics. Some examples include polypropylene, polyester, vinyl, or special heat-sensitive materials which offer water, tear, and fade resistance.

For instance, in the express logistics industry, electronic shipping labels have been widely used in recent years. To achieve better waterproofing, high-end markets have started to massively adopt "triple-proof" thermal paper for printing electronic shipping labels. This type of thermal paper applies an extra protective layer on top of the normal thermal color layer, thus providing superior waterproofing, oil resistance, and abrasion resistance.

In addition to waterproofing, sometimes you also need to consider the application scenario to further select the right label material. For example, if you need a waterproof label suitable for outdoor advertising or industrial equipment identification, vinyl is an excellent choice among the range of available label materials. Labels made from this material have good weather resistance, wear resistance, and adhesiveness, and can be clearly and vividly printed with patterns and text using thermal transfer or inkjet printing methods, enhancing visual effects and recognition.

b) Choose the right label printer:

Based on the selected waterproof label material, choose a label printer that supports the desired printing technology (direct thermal, thermal transfer, laser, or inkjet) and is compatible with the material.

For example, a direct thermal label printer is suitable for printing labels on heat-sensitive materials, while a thermal transfer label printer is more versatile and can be used for a wider range of label materials like PP, and PET.

As a professional printer device R&D and manufacturing company, HPRT offers various types of thermal printers which are widely used in industries such as logistics, manufacturing, medical, warehousing, and more. If you have any questions about our thermal label printers , please feel free to contact us. HPRT professional team is fully committed to providing you with related support.

c) Design your label:

Use label design software to create your custom labels, ensuring it includes all necessary information and is formatted for the label size. It’s highly recommended that you should read the article “Custom Label Heaven: Create Unique Labels with Your Thermal Transfer Label Printer” to obtain more details about creating custom labels.

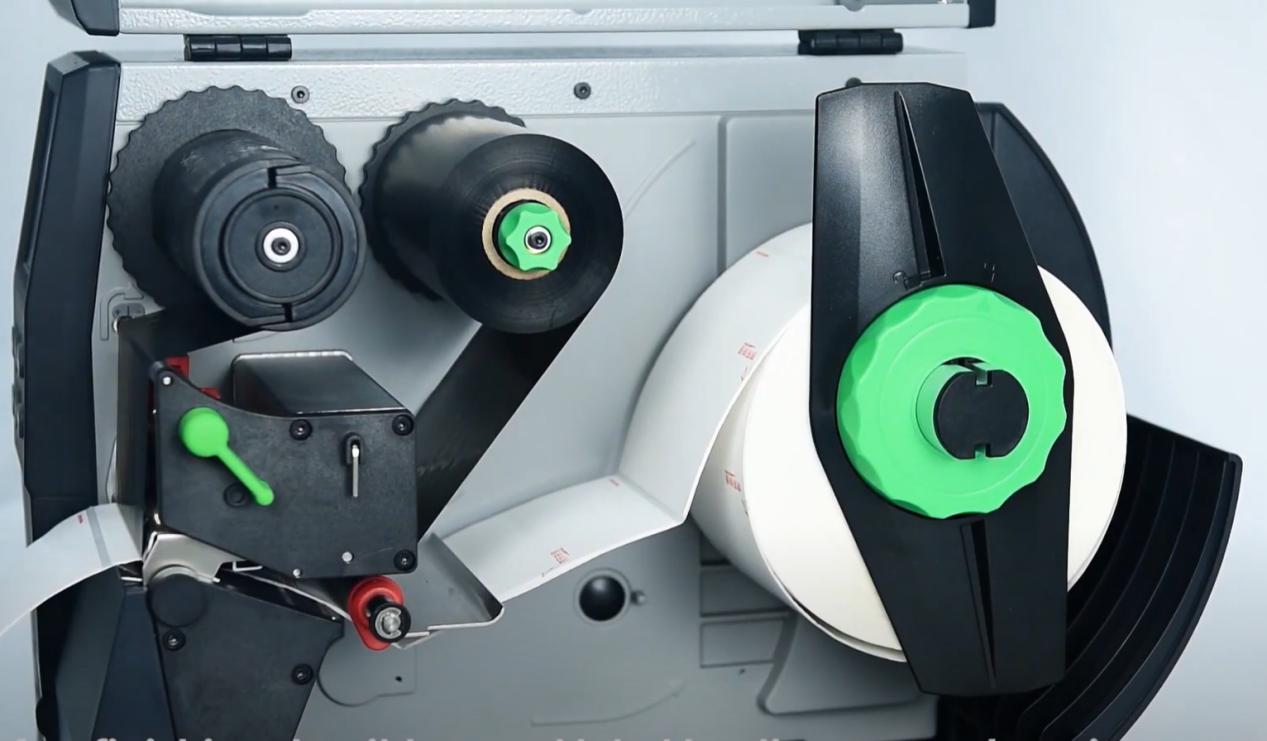

d) Load the waterproof label material:

Follow the manufacturer’s instructions to load the waterproof label material into the label printer. Confirm the installed label roll corresponds with the designated label size.

e) Print a test label:

Adjust the printer settings according to the label material and desired print quality. Before printing the entire batch of labels, print a test label to ensure the design and print quality are satisfactory. If everything is OK, you may conduct batch printing.

Waterproof label printers craft high-quality, durable labels, acting as a robust "armor" for your products. These labels, clear and visible even in harsh conditions, effectively deliver information while adhering to stringent industry regulations. Whether you manage an outdoor equipment store, direct a food and beverage company, or operate in any field requiring waterproof labels, investing in a reliable waterproof label printer is a strategic step to elevate your product’s image and enhance customer satisfaction.