A Guide to 5 Types of Safety & Warning Labels: Applications and Benefits

In daily life, we often come across various safety warning labels. Whether in the workplace, public spaces, or on consumer products, these labels provide important information about potential hazards and guide us to take safe actions. By choosing a suitable label printer, your company can efficiently produce high-quality labels that comply with standards and regulations, enhancing compliance and safety communication. This article will introduce the five types of safety warning labels and their applications, and provide valuable insights to help you select the right label printing machine.

1. What Are Safety Warning Labels?

Safety warning labels are labels that serve as reminders, alerts, and provide relevant safety information. They are commonly used in various settings and environments, including workplaces, public spaces, industrial facilities, and consumer products. The purpose of these labels is to protect individuals and property from potential risks and hazards and promote the formation of safety awareness and behavior.

Safety warning labels serve multiple purposes:

a) Alerting potential hazards: Safety warning labels can alert people to potential dangers or risks, such as high-pressure areas, chemical storage areas, etc.

b) Reminding of safety measures: These labels can remind people to take necessary safety measures, such as wearing personal protective equipment, using tools and equipment correctly, and informing users of the necessary preventive measures.

c) Guiding emergency actions: In emergency situations, safety warning labels can guide people to locate safety exits, emergency equipment, or points of assistance, helping them respond to unforeseen events.

d) Providing relevant information: Safety warning labels can provide relevant safety information, such as emergency contact numbers, storage requirements for items, usage instructions, etc., to assist people in proper handling and operation.

It is important to note that many countries have established relevant laws and requirements to ensure the accuracy, readability, and consistency of safety warning labels. These regulations include content design and placement requirements for safety labels, aiming to enhance safety awareness and reduce potential risks. By setting clear and understandable labels, businesses can reduce the risks of accidents, injuries, and potential legal issues.

2. Common Types of Safety Warning Labels and Their Applications

Safety warning labels are used in various industries, and each type of label has its specific purpose and application. Here, we will discuss several common types of safety warning labels and their real-life applications, providing vivid examples to help you understand their importance.

a) Industrial safety labels

Application: Workplace and industrial environments

Industrial safety labels are widely used in workplaces and industrial environments such as factories, manufacturing industries, and construction sites. Their purpose is to provide necessary safety information, ensuring that workers adhere to proper operations and protective measures to ensure workplace safety and health. These labels are typically affixed to industrial equipment, machinery, or hazardous areas in industrial environments.

Here are some examples of common industrial safety labels:

- Machine safety labels: They alert specific machine’s potential dangers and remind workers of the operating, maintenance, and personal protective equipment regulations they need to adhere to.

- Chemical hazard labels: They identify the hazards of chemicals and provide information on their safe handling, including safety data, hazard levels, protective measures, and emergency response procedures.

- High-temperature warning labels: They indicate high-temperature areas or equipment and remind workers to be aware of the heat hazards. They include temperature warnings, burn prevention tips, and appropriate personal protective measures.

- Electrical safety labels: They identify the potential hazards of electrical equipment and provide information on their proper usage, including risks of electric shock, electrical grounding requirements, equipment maintenance, and operating guidelines.

- Heavy lifting labels: They remind workers of safe practices for lifting and moving heavy objects, including maximum load limits, proper lifting techniques, and guidance on using auxiliary equipment.

b) Fire safety stickers and caution labels

Application: Public Areas and Buildings

Fire safety labels provide important information about fire safety measures, such as the location of fire extinguishers, emergency exits, and evacuation routes. In public buildings like shopping malls, these labels can guide visitors to safe locations in the event of a fire, reducing the risk of injuries and fatalities.

Caution labels in public places are commonly used to alert people to potential dangers or to comply with specific safety regulations. For instance, in hospital ambulance lanes, prohibition labels remind people not to park or block the passage, ensuring swift access during emergencies. These labels serve as reminders and enforce behavioral regulations, ensuring safety and order in public places.

c) Healthcare labels & first aid stickers

Application: Medical facilities and public areas

Hospitals, clinics, and laboratories use medical safety labels to indicate the potential hazards of biological materials, radiation exposure risks, and other potential dangers for employees, patients, and visitors. In public areas such as parks, entertainment facilities, and public buildings, emergency labels guide people to find first aid kits, defibrillators, or emergency call stations to address accidents or medical emergencies.

d) Transportation warning labels

Application: Warehousing, transportation, and shipping sectors

Transportation safety labels are used to identify and indicate hazardous materials, flammable substances, corrosive substances, and other special cargo during transportation. These labels provide information about proper handling, packaging, and storage requirements to ensure safety during transportation. They may also include specific handling precautions and emergency response guidelines.

e) Product warning labels

Application: Food, beverages, personal care, household, electronics, etc.

These product warning labels are typically placed in prominent positions, such as the front or back of food packaging, toy boxes, or the body of electronic products. They are designed to provide consumers with information about product usage, maintenance, and safety precautions.

Product warning labels play a crucial role in different fields. For example, in the food industry, they provide key information such as food ingredients, nutritional value, storage conditions, and allergen information. And labels on toys and children’s products provide age recommendations, safety tips, and potential hazard warnings to protect children’s safety.

3. Benefits of Safety Warning Label Printers

By understanding the wide-ranging applications of safety warning labels in various industries, we can clearly recognize their importance in enhancing employee safety and overall work environment. Now, let’s further explore the benefits of having a dedicated safety warning label printer for your business.

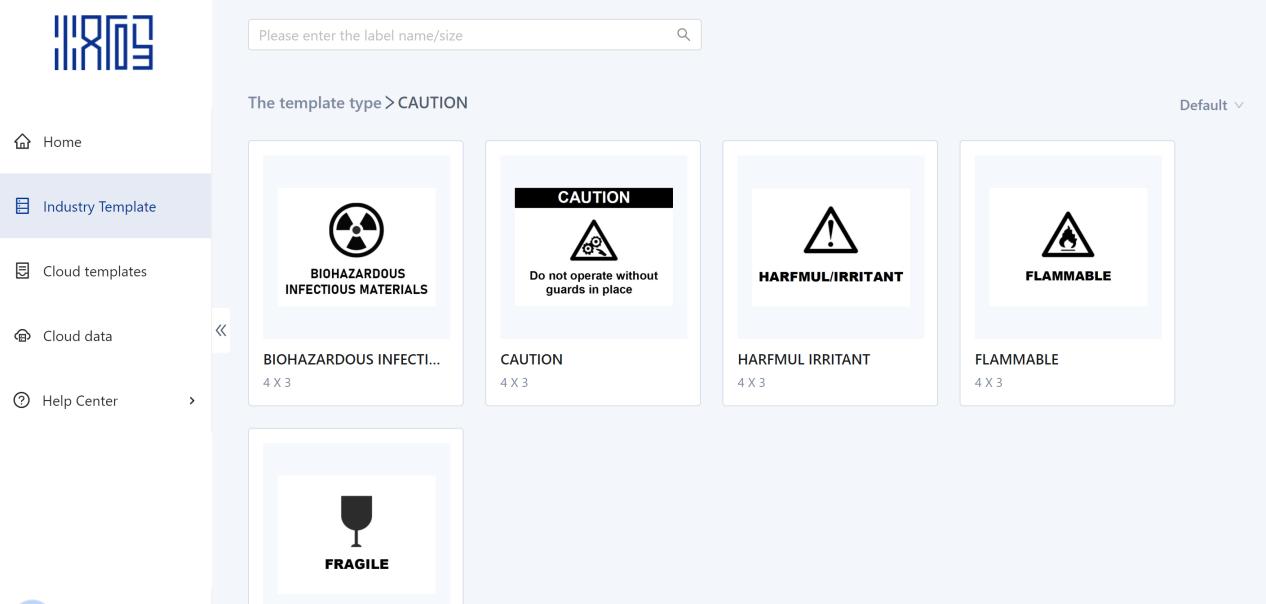

a) Custom warning labels

Investing in a label printer offers advantages over purchasing pre-made labels as it allows you to customize labels to meet your specific requirements. You may need special sizes or labels with specific properties like durability, waterproofing, UV resistance, etc. You can choose from numerous templates or design your own labels, incorporating company logos, specific warning messages, etc.

b) Cost-Effectiveness

Having your own safety warning label maker can save your business long-term costs. By printing labels as needed, you can avoid the expense of purchasing pre-printed labels and reduce unnecessary inventory requirements.

c) Enhanced Compliance

Using a label printer allows you to update and adjust labels according to the latest safety standards, regulations, or company policies. This ensures that your labels consistently meet the latest safety requirements, keeping your business compliant.

d) Better Quality Control

By printing safety labels in-house, you have control over the materials and printing quality, ensuring durable, legible labels that can withstand various environmental conditions.

4. Choosing the Right Safety Warning Label Printer

With numerous types of label printers available in the market, how do you select the right printer for your business? Consider the following key factors:

- Printer Types

- Print resolution and speed

- Label size and material compatibility

- User-friendly interface and software

There are several types of printers available for you, including thermal transfer, inkjet, and laser label printers. It’s highly recommended for you to read the article title “Direct Thermal, Thermal Transfer, Inkjet, and Laser Label Printer- Which One to Choose?” for more knowledge about these types of printers.

While most label printers can produce clear and legible labels, for labels with small fonts or symbols, it is advisable to choose a printer with higher resolution to ensure precise printing. However, it is important to strike a balance between printing quality and speed to meet your specific needs.

The size and material of the label you intend to print will determine which printer is suitable for your needs. Some printers are only compatible with specific label sizes or materials. For example, thermal transfer label printers excel at printing small-sized labels with widths like 4 inches or 6 inches.

The interface and software of the printer should be user-friendly and intuitive, allowing for easy operation and setup. A simple and user-friendly interface can save time and reduce frustration, while robust software can provide advanced features and customization options.

For small businesses, here is an entry-level safety warning label printer HPRT HT330 for you. This 4-inch thermal transfer label printer is reasonably priced and capable of producing durable safety labels. It covers a printing width ranging from 1 inch to 4 inches, making it suitable for warning label printing needs.

The HT330 label printer has a resolution of 300 dpi, which is sufficient for most printing needs and fine details. It is compatible with various label materials such as vinyl, PVC, and PET. Additionally, its compact design minimizes office space requirements. Whether you need transportation warning labels, electrical safety labels, or chemical safety labels, this printer can quickly generate clear, sharp, and high-quality labels.

Furthermore, HPRT offers you the free label design and barcode generator software - HPRT Herelabel. With its robust editing functions and vast collection of label template resources, this software enables you to fully customize your labels according to your preferences.

5. FAQs about Safety Warning Label Printers

Q: Can I print safety warning labels in multiple languages?

A: Yes, most label printer software allows you to create labels in various languages, ensuring that your safety and warning labels are accessible to a diverse audience.

Q: How do I maintain my safety warning label printer?

A: Regular maintenance, such as cleaning the print head and replacing consumables, will help prolong the lifespan of the label printer. For specific instructions, please refer to the manufacturer’s maintenance guide.

Q: Can I print labels on different materials?

A: Many safety warning label printers are compatible with various materials such as vinyl, polyester, and polypropylene. Please consult the printer’s documentation to ensure it supports the label materials you require.

Q: What is the lifespan of safety warning labels?

A: The lifespan of safety warning labels depends on several factors, including the quality of the label material, environmental conditions, usage methods, and frequency. Generally, high-quality safety warning labels can have a long lifespan, often lasting for several years.

6. Conclusion

Upon reviewing the entire article, it becomes evident that the five types of safety warning labels discussed hold a pivotal role in various industries. Not only do they enhance work efficiency, but they also establish a robust safety line for both employees and consumers. Equipping your business with the appropriate label printer empowers you to create customized, durable, and informative safety warning labels, effectively reducing the risks of accidents and injuries.

By providing this article, our intention is to provide you with practical insights into the significance and value of safety warning labels and their printers. Through understanding their importance and acquiring knowledge on selecting the suitable label printer, you can confidently take proactive measures to enhance workplace safety and efficiency.