Barcode Inventory Systems and Scanners: Top 5 Questions Answered

A Barcode inventory system is a technology solution that uses barcodes to manage and track product quantities, orders, and sales in real-time. It greatly enhances warehouse management efficiency and reduces operational costs. If you're considering implementing a barcode inventory system, you may have some questions. This post addresses the top 5 questions about barcode inventory systems and barcode scanners.

What is the Difference Between Barcode and RFID Inventory System?

Businesses often face the decision between barcodes and RFID systems. They are two different technologies used for inventory tracking.

Barcode systems use 1D or 2D barcodes to store data. And inventory barcode scanners capture the data encoded in barcodes and feed it into a system for item-level identification and inventory tracking.

RFID stands for radio-frequency identification. RFID is a technology that uses radio waves to communicate with RFID tags.

These tags can store detailed information about items and can be quickly detected by RFID readers over a wide range. This facilitates swift data exchanges, such as the updating of inventory statuses, all within seconds. RFID system is a more intelligent approach to warehouse management.

When deciding between barcode and RFID inventory systems, consider the three most important factors:

1. Cost

Barcode systems are generally less expensive to implement and maintain than RFID systems.The cost of barcode labels and scanners is typically lower than that of RFID tags and readers.

For businesses with limited budgets or those that require a simple tracking solution, barcodes might be the more cost-effective option.

2. Read Range and Speed

RFID tags can be read from a distance and do not require a direct line of sight, allowing for faster scanning of multiple items. This is particularly beneficial in environments where speed and efficiency are critical.

3. Complexity and Scalability

RFID systems offer more complexity and scalability than barcode systems.

They can handle large volumes of items simultaneously, making them suitable for businesses with extensive inventory or those that need to track items through multiple stages.If the business anticipates growth or has a complex supply chain, RFID might provide a more scalable solution.

What is the Best Barcode Type for Inventory? What Type of Barcode is Used in Warehouse?

A critical step in implementing a barcode system is to determine the appropriate barcode symbology. The best barcode type for inventory depends on your specific needs. You should carefully consider your requirements of the inventory system, nature of the items being tracked, and specific operational environment.

For example, small, delicate items may require a high-density barcode. And some barcode formats are more resilient or can be printed on more durable materials than others.

Here's a quick look at some of the most prevalent barcode types and their suitability for warehouse inventory:

● UPC-A: This is the most common barcode type used in retail. It is a well-established and universally recognized 12-digit code used to identify products.

● EAN-13: This is the European equivalent of the UPC-A barcode. It is a 13-digit code that is used to marking products often sold at retail point of sale.

● Code 128: Highly versatile and capable of encoding all 128 characters of the ASCII character set. Code 128 is used extensively in logistics and transportation for packaging and shipping.

● Interleaved 2 of 5 (ITF): Often used in warehousing, distribution, and logistics for cartons and pallets. It can only encode numbers, and is efficient for squeezing long numeric data sequences into compact space on labels.

● QR Code: Increasingly used in inventory management for their ability to encode more data than traditional barcode, including URLs, serial numbers, and other information. It can be scanned using smartphones and scanners, making them accessible for various applications.

What Is Inventory App? Is There a Free App to Scan Barcodes for Inventory?

An inventory app is a software program that assist in tracking inventory levels, orders, sales, and deliveries on the go. They can be installed and used on various mobile devices, including smartphones, tablets, and PDAs, and are often compatible with Android and iOS operating systems.

There are many different inventory apps available, both free and paid. Some popular free inventory management apps include:

1. Sortly

Sortly offers a highly visual inventory management system, allowing users to organize items using photos, tags, and customizable categories. It supports QR code and barcode scanning, tacking items with it becomes easy. This inventory app also enables users to create and export custom reports and lists.

Available on iOS and Android devices, Sortly works well on both smartphones and tablets, offering a flexible solution for inventory management on the go.

2. Zoho

Zoho Inventory app provides a comprehensive set of tools for inventory management, including order management, end-to-end tracking, and automation of order fulfillment processes. It integrates well with other Zoho apps and various third-party applications like Amazon, eBay, Shopify, and more, ideal for businesses involved in e-commerce.

Zoho offers apps for iOS and Android, suitable for use on smartphones and tablets. It also works on desktops via web browsers.

3. Stockpile by Canvus

Stockpile is a free online inventory system designed for small to medium-sized businesses. It offers features such as multiple locations, sub-locations, and the ability to record sales and returns. Users can also manage users' access levels and generate detailed reports.

Being a web-based application, Stockpile is accessible from any device with an internet connection, including smartphones, tablets, and desktop computers, through web browsers.

How Do I Use Inventory Scanner in Excel? How Do I Scan Inventory into Excel?

Small businesses and startups might consider using Excel as an inventory system platform due to limited budgets and simple inventory needs at the initial stage.

In this scenario, inventory barcode scanners can be incredibly helpful in streamlining tasks like product inflow/outflow and physical inventory counting.

To facilitate data entry in Excel, you should configure the barcode scanner correctly. Specifically, you need to configure the barcode scanner to automatically wrap to the next cell after each scan.

For more detailed instructions, please read the blog post "How to Use a Barcode Scanner in Excel."

What's the Best Inventory Scanner?

It's challenging to find an inventory scanner gun that fits all scenarios. A wise choice can only be made by considering the specific needs and use cases.

1. Need a scanner for fixed stations?

HPRT N101 2D barcode scanner is your ideal choice. This inventory scanner gun can be used at qualify control stations, distribution centers and manufacturing facilities where inventory is received, processed, or shipped.

● Accurate and Fast Decoding

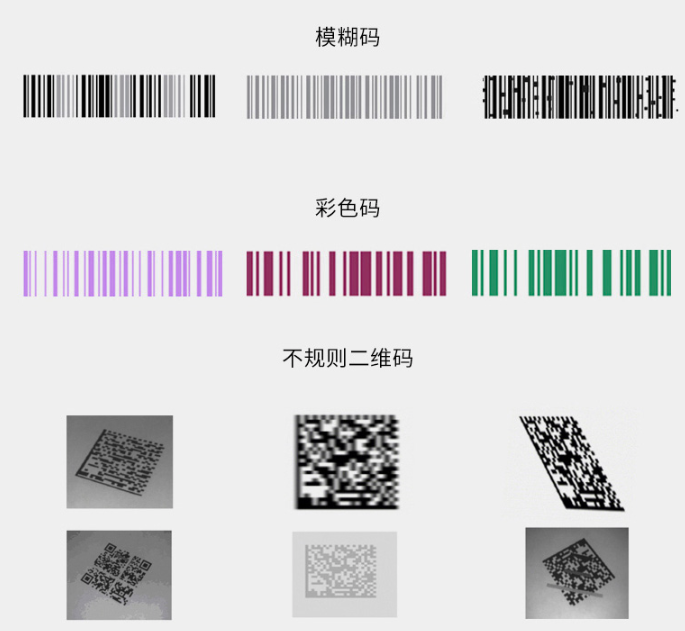

It reads various barcodes, including paper, mobile QR codes. With advanced CMOS image capture technology, N101 can even decode highly-distorted barcodes, fuzzy barcodes, color codes, and irregular QR codes.

● Rugged and Durable Construction

The body is made of PC material, with the top and tail of the scanner gun covered in TPU for a comfortable grip. It's shock and drop-resistant, with a button life of up to 5 million presses.

Moreover, the data cable is bend-resistant, capable of bending 45 degrees to the left and right, ensuring more stable data transmission.

● Versatile Scanning Modes

The N101 offers two scanning modes to optimize your workflow. For precise control over scanning small items or densely packed barcodes, use the manual button mode. For high-volume scanning scenarios like warehouse dispatch, the automatic sensing mode takes over, triggering a scan as soon as an object enters the scanning area.

With it, operators can quickly scan items without worrying about connectivity issues or battery life, ensuring efficient processing.

2. Need mobile inventory management?

For advanced mobile inventory management needs such as stock inquiry, physical counting, and mobile receiving and shipping, the HPRT M2 PDA handheld terminal is highly recommended.

This Android rugged PDA lets you to perform inventory tasks anytime, anywhere, such as conducting physical counting, receiving, and picking directly in the warehouse, meeting more complex inventory management requirements.

The HPRT M2 handheld terminal supports downloading various warehouse management apps, enabling you to quickly generate inbound and outbound delivery notes, access inventory data in real time, and enhance coordination across different departments.

Struggling with inefficient inventory management? Let HPRT show you the way! HPRT is a powerful China suppiler of barcode inventory system hardware, including scanners, PDAs, and barcode printers.

Our solutions will streamline your operations and boost your bottom line. Whether you're starting fresh with a barcode system for inventory or looking to optimize your existing setup, HPRT is here to help. Feel free to contact us and get your custom barcode inventory products.