Designing High-Quality Barcode Label: Essential Factors to Consider

How to efficiently manage a company’s inventory, transportation, and logistics operations? High-quality barcodes are a key element that can seamlessly connect the entire supply chain. Thermal transfer label printers have become the preferred solution for producing these high-quality and durable barcodes. If you want to learn how to print high-quality barcodes using a thermal transfer label printer, this article will guide you through each step to easily master the techniques.

Understanding Thermal Transfer Label Printers

Thermal transfer printing is a widely used method for creating long-lasting, high-quality barcodes. It involves the use of heat to transfer ink from a ribbon onto a label material, resulting in a sharp and durable print. Key components of thermal transfer printers include the printhead, platen roller, and ribbon supply spindle. These printers offer several advantages over direct thermal printing, including better print quality, resistance to fading, and the ability to print on a wide range of label materials.

Choosing the Right Thermal Transfer Printer

When evaluating different printer models, you need to carefully consider factors such as print volume, print speed, maximum print width, and resolution, among others. In addition, some easily overlooked factors such as connectivity options and ease of operation also need to be carefully considered.

HPRT, a professional manufacturer of printing equipment, provides various types of high-performance printer products. Over the years, HPRT has been committed to improving product quality and promoting technological innovation, making it a trusted supplier of label printers in the global market.

HPRT HT330 boasts a high-resolution output of 300 dpi (12 dots/mm) and printing speeds of up to 4 ips. It supports a wide range of printing widths, from 25.4mm to 106mm, and can handle various media types, such as roll-fed, fan-fed, die-cut, continuous label, and tag stock. It is a reliable and efficient choice for printing high-quality barcode labels, suitable for various industries, such as logistics, healthcare, retail, and manufacturing.

Choosing the Right Ribbon Type

Thermal transfer ribbons come in three main types: wax, wax-resin, and resin. Please read the article “Three Types of Thermal Transfer Ribbons” to learn more about the basics of thermal transfer ribbons and make the right choice for your needs.

Choosing the Right Label Material & Size

Choosing the appropriate label material is crucial to ensure the barcode’s lifespan and readability. Common label materials include paper, polyester, and polypropylene, each offering unique characteristics and benefits.

When determining the ideal label size, consider the amount of information you need to include and the scanning distance requirements. Also, choose the adhesive that is suitable for the label sticking surface while considering factors such as temperature, humidity, and surface texture.

High-Quality Barcode Designing

A successful barcode system relies on the quality of the barcodes themselves. Poorly designed or unreadable barcodes can lead to scanning errors and inefficiencies. To ensure your barcode labels are of the highest quality, consider the following factors:

A. 1D barcodes vs. 2D barcodes

There are two main types of barcode symbologies: 1D (one-dimensional) and 2D (two-dimensional). 1D barcodes, such as Code 128, UPC, and EAN, are composed of a series of vertical lines and spaces that represent data. These barcodes are easier to read and have a lower printing cost but can only store a limited amount of data.

2D barcodes, such as QR codes and Data Matrix, use patterns of squares, dots, or other shapes to encode data. They can store a larger amount of data, including text, numbers, and even URLs. However, 2D barcodes may require more advanced scanning equipment and have a slightly higher printing cost.

Choose the barcode type that best fits your data storage needs and is compatible with your scanning equipment.

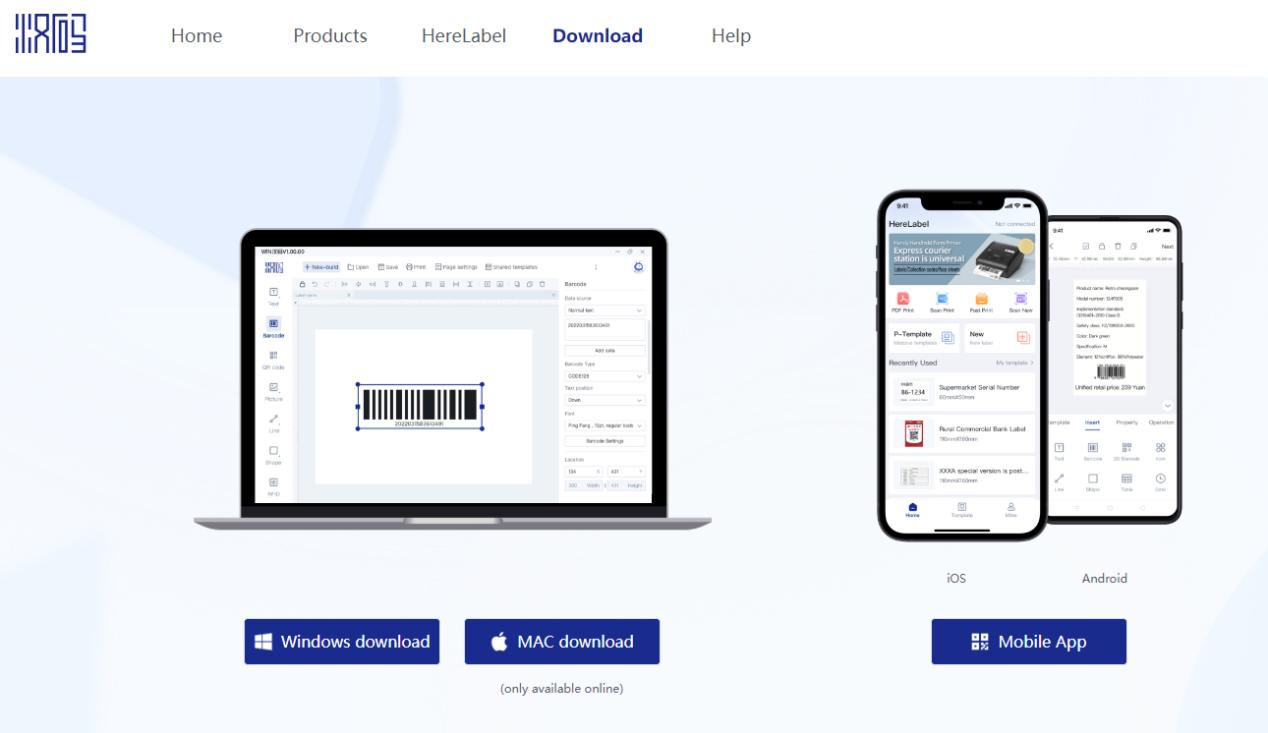

It is worth mentioning that, HPRT Herelabel, a free barcode generator software allow users to customize barcode labels, and supports barcode generating covering 2d codes. It’s available for users to register now.

B. Creating readable and scannable barcodes

For a barcode to be easily scannable, it must meet specific requirements:

Ensure sufficient contrast:

The bars and spaces in a barcode must have enough contrast to be distinguishable by a scanner. Typically, this means using black bars on a white background, but other high-contrast color combinations may also work.

Here are some barcode label examples for you. Some businesses may choose clear barcode labels to better showcase their beverage inside the bottles, however, they forget that transparent barcode labels will be difficult to recognize during scanning due to insufficient contrast, which may result in recognition errors or failures during scanning.

Another typical example is shipment exception. If your waybill is too dirty, it may obscure the black and white stripes on the barcode, affecting the contrast of the scanning device and causing barcode label unreadable. So the logistic carrier would print a new label and replaced the old one.

Maintain proper quiet zones:

A quiet zone is a clear space around the barcode that helps scanners distinguish the barcode from surrounding elements. For most 1D barcodes, the quiet zone should be at least 10 times the width of the narrowest bar.

Optimize the aspect ratio:

The aspect ratio is the relationship between the width and height of a barcode. If the aspect ratio is too wide or too narrow, the barcode may be difficult to scan. Consult the specifications for your chosen symbology to determine the ideal aspect ratio.

Print at an appropriate resolution:

Low-resolution printing can cause the bars and spaces in a barcode to blur, making it difficult to scan. Ensure your thermal transfer printer is set to a suitable resolution, usually between 203 and 600 dpi, for crisp barcode printing.

Printer Settings for Optimal Barcode Quality

To achieve the best possible barcode quality, it’s essential to configure your thermal transfer printer settings correctly. Consider the following factors when adjusting your printer settings:

A. Print speed and temperature considerations

The print speed and temperature settings on your thermal transfer printer can impact the quality of your barcodes. Printing at a higher speed may result in lower print quality, while using too much heat can cause the ribbon to burn through and produce a blurry or smeared barcode. Experiment with different speed and temperature settings to find the optimal balance for your specific printer, ribbon, and label material combination.

B. Print resolution and sharpness

The print resolution of your thermal transfer printer directly affects the sharpness and readability of your barcodes. Higher resolution printers can produce more detailed and crisp barcodes but may have a slower print speed and higher consumable costs. Determine the minimum resolution required for your barcode symbology and choose a printer that meets or exceeds this specification.

C. Calibrating the printer for accuracy

Proper calibration is crucial for ensuring that your thermal transfer printer accurately prints barcodes on your chosen label material. Calibration typically involves adjusting the printer’s sensors to detect the gaps between labels and align the print correctly. Consult your printer’s user manual for specific calibration instructions, and be prepared to recalibrate the printer when you change label materials or ribbon types.

Barcode Verification and Validation

Ensuring that your barcodes meet industry standards and are easily scannable is vital for maintaining efficiency in your operations. Verification and validation processes can help you maintain high-quality barcodes.

A. The importance of barcode testing

Regularly testing your barcodes ensures that they are consistently readable and compliant with any applicable industry standards, such as GS1 or ISO/IEC. Testing can identify issues with print quality, symbology, or data encoding before they lead to costly errors or inefficiencies in your workflow.

B. Barcode verifiers and scanners

A barcode verifier is a specialized device used to verify and scan barcodes for compliance with standards and specifications. It’s a specialized device designed to grade the quality of printed barcodes based on factors such as contrast, modulation, and quiet zone size. By using this type of specialized equipment, the accuracy and readability of the barcode can be ensured, avoiding problems such as logistics errors and inventory confusion caused by non-compliant barcodes.

Barcode scanners, on the other hand, are used to read and decode the information stored in barcodes. While they do not provide quality grading like verifiers, they can be used to quickly check if the barcode is recognizable and contains the correct data.

C. Ensuring compliance with industry standards

Adhering to industry standards for barcode quality ensures that your barcodes are compatible with other systems and scanning equipment, minimizing the risk of errors or rejected products. Research the specific requirements for your industry or application, and use barcode verifiers or scanners to ensure that your barcodes meet these standards.

Conclusion

High-quality barcoding is essential for efficient and accurate data collection and tracking in various industries. By understanding the components of thermal transfer label printers, choosing the right consumables, designing effective barcodes, and optimizing printer settings, you can master the art of high-quality barcoding.