Five Common Mistakes to Avoid When Using a Thermal Transfer Label Printer

In the swift-paced realm of present, firms bank on barcodes for expedient operations, stock administration, and spot-on tracing. A variety of thermal transfer label printers are widespread for generating top-notch, lasting barcodes. Nonetheless, several typical blunders might culminate in printing slip-ups and adversely affect the utility of the barcodes. Up next, we shall converse about the prevalent missteps to dodge when utilizing a thermal transfer label printer, assuring top performance and first-rate barcode printing.

Picking the Erroneous Printer Model

A. Printing requirements and printer competencies at odds

A frequent error is opting for a printer that fails to match your particular printing necessities. Confirm that the printer’s capabilities, like print resolution, swiftness, and connection alternatives, are in sync with your barcode printing requisites.

B. Disregarding indispensable traits

In the course of picking a printer, it’s vital to mull over all the compulsory features, like compatibility with a range of ribbon and label materials, user-friendly interface, and easy maintenance. Not doing so may result in less-than-ideal printing outcomes.

Unfit Ribbon and Label Pick

A. Incompatible ribbon and label materials

Employing an incorrect ribbon and label pairing might result in subpar print quality and diminished durability. Ascertain that you pick a ribbon that’s well-suited with your preferred label material for ideal printing outcomes.

B. Unfit label adhesive for the usage

Settling on the wrong label adhesive might provoke labels to detach or stick inadequately. Contemplate the surface and application milieu when selecting an adhesive to make sure the labels stay in position.

Crafting Low-Quality Barcodes

A. Picking an unsuitable barcode symbology

Opting for the incorrect barcode symbology for your application may lead to uninterpretable or unscannable barcodes. Bear in mind factors such as the amount of data, type of data, and scanning environment when selecting a symbology.

B. Insufficient contrast between barcode and backdrop

For a barcode to be legible, ample contrast between the barcode and its background is required. Make certain that the ribbon color and label background supply adequate contrast for effortless scanning.

C. Securing optimal barcode legibility and scannability

To devise high-quality barcodes, employ suitable barcode design software, uphold the correct aspect ratio, and steer clear of using small fonts or exceedingly intricate designs. Consistently test your barcodes using a scanner to ensure their legibility and scannability.

Here Label software under HPRT is a professional barcode generator and label design software. It is free to use for label design and barcode generator after a simple registration. This software provides a rich set of industry templates and various label editing functions, which are easy to operate. It also supports cloud storage of label templates, so you don’t have to worry about losing them.

Subpar Maintenance and Cleansing

A. Disregarding regular cleaning routines

Overlooking regular upkeep and cleaning might result in diminished print quality and printer malfunctions. Adhere to the manufacturer’s suggestions for cleaning and care to guarantee top performance.

B. Inappropriate storage of ribbons and labels

Storing ribbons and labels improperly might make them deteriorate, culminating in poor print quality. Preserve them in a cool, dry place away from direct sunlight to maintain their quality.

C. Consequences of inadequate maintenance on print quality

Insufficient maintenance might give rise to issues like uneven print density, smearing, or ribbon wrinkling. By carrying out regular maintenance and cleaning, you can avert these problems and sustain high-quality printing.

Dismissing Environmental Aspects

A. Neglecting the influence of temperature and humidity

Temperature and humidity might impact the performance of your thermal transfer label printer and the quality of your printed barcodes. Monitor the environment where you print and store your labels, making adjustments as needed to maintain optimal conditions.

B. Failing to consider exposure to chemicals or abrasion

In some applications, barcodes may be exposed to chemicals or abrasion, which can affect their readability. Choose label materials and ribbon types that can withstand these conditions to ensure the longevity of your barcodes.

C. Adapting to the specific application environment

Understand the environment in which your barcodes will be used and select materials and printer settings accordingly. This will help maintain the quality and functionality of your barcodes, regardless of the conditions they face.

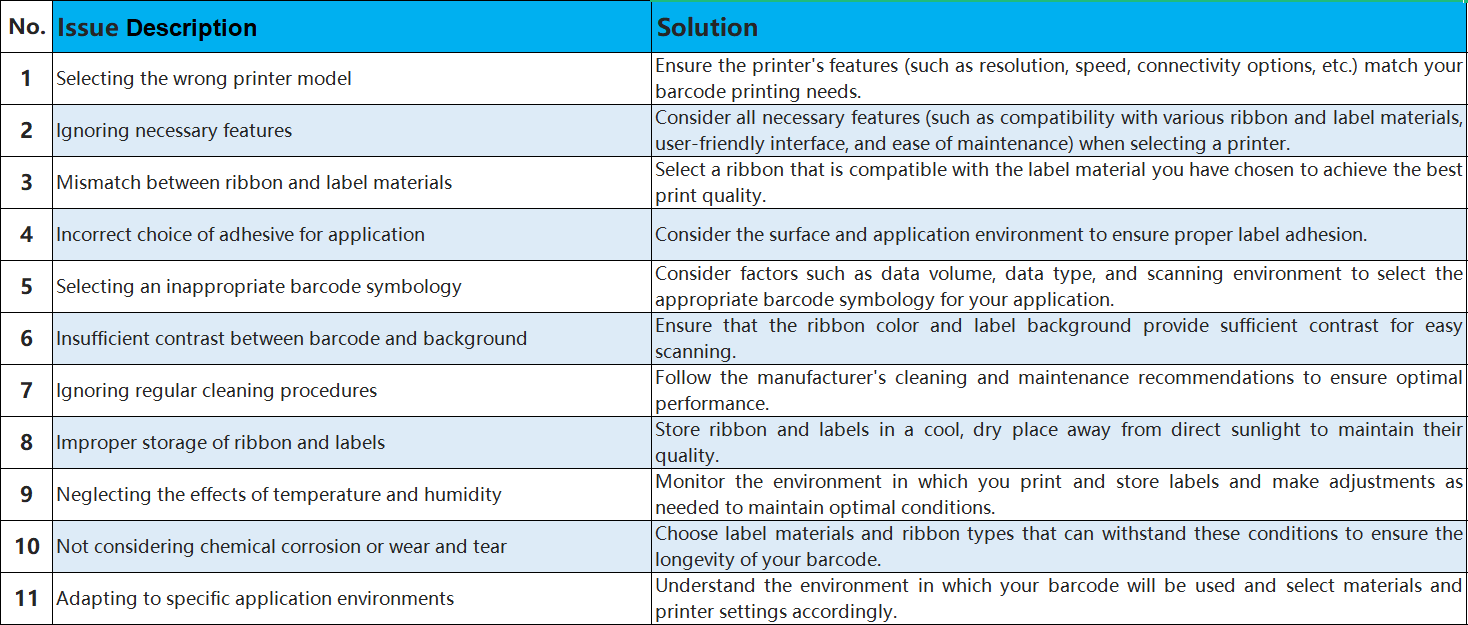

Use this troubleshooting checklist below to help you review the above and visualize these common errors and how to solve them.

Concluding Thoughts

By steering clear of these common missteps, you can ensure that your thermal transfer label printer produces first-rate, durable barcodes. Make informed decisions when selecting a printer, ribbon, and label materials, and maintain your printer properly.

Attention to detail and adherence to best practices in every aspect of thermal transfer label printing are crucial for achieving optimal results. By being diligent, you can consistently produce high-quality barcodes that meet industry standards and support the efficient operation of your business.