Clear Label vs. White Label Printer: Which One Is Right for You

In the previous article, we have already shared how to choose the right type of label printerfor your needs. However, even if you have acquired this knowledge, you may still encounter confusion in practice. For instance, when it comes to labeling products, should you opt for clear labels or white labels? Which type of label printer is more suitable? In the following discussion, we will comprehensively compare and analyze the advantages and disadvantages of clear label printers and white label printers to assist you in making a more informed decision.

Determining the Label Type - Clear Labels or White Labels

Firstly, let us begin by determining our label requirements - choosing between clear labels or white labels.

1. Clear Labels:

Clear labels for printing are a popular option for many businesses, especially those in the food and beverage industry. These labels have a transparent background, allowing the product to be seen through the label itself. Some common applications of clear labels include product packaging, window displays, and labeling containers or bottles.

Clear labels with transparent backgrounds are commonly used in a variety of industries and applications, including food and beverage packaging, cosmetics and personal care products, and health and wellness products.

In the food and beverage industry, clear labels are employed to showcase the natural color and texture of the product, creating an authentic and organic feel.

In the cosmetics and personal care industry, clear labels allow customers to see the product inside the packaging before making a purchase.

They are also utilized in the health and wellness industry to provide detailed ingredient information or dosage instructions on supplement bottles or packaging.

a) Pros of Clear Labels

Aesthetic appeal: Clear labels provide a sleek and modern look that is ideal for products with a minimalist or contemporary design. They can also be used to create a "no-label" look, where the label appears to be printed directly on the product itself. This can be particularly effective for high-end or luxury products where a premium look and feel is important.

Versatility: Clear labels can be printed on a variety of materials, including vinyl, polyester, and polypropylene, making them suitable for a wide range of applications. They are also available in a variety of shapes and sizes, making them easy to customize to fit specific packaging requirements.

Enhanced product visibility: Clear labels provide a full view of the product inside the packaging, allowing customers to see exactly what they are buying. This can be particularly effective for products with unique shapes, textures, or colors that are difficult to showcase with traditional white labels.

b) Cons of Clear Labels

Limited readability in certain situations: Clear labels can be more difficult to read in certain lighting conditions or against certain backgrounds. This can be a concern for products that require detailed or extensive labeling, as it may be difficult for customers to read the information on the label.

Potential compatibility issues with certain surfaces: Clear labels may not adhere as well to certain surfaces as traditional white labels. This can be a concern for products that require labels to be highly durable or long-lasting, as the label may peel or come off over time.

2. White Labels

White labels are another popular option for printing labels. Unlike clear labels, white labels have an opaque background, making them more suitable for products that require detailed information or have specific design requirements.

White labels are commonly used in the food and beverage industry, retail packaging, and shipping and logistics. They are also popular for industrial applications, where they can be used for asset tracking, inventory management, and other labeling needs.

a) Pros of White Labels

High contrast and readability: White labels offer high contrast and readability, especially those with barcodes or qr codes, making them easy to read and scan in a variety of lighting conditions and against a range of backgrounds.

Greater compatibility with various surfaces: White labels are more versatile than clear labels and can be used on a wider range of surfaces, including paper, plastic, glass, and metal. When it comes to adhering labels to various surfaces and ensuring long-lasting durability, white labels are undoubtedly the preferred choice.

Cost-effectiveness: White labels are often less expensive than clear labels, making them a more cost-effective option for businesses on a tight budget.

b) Cons of White Labels

Limited suitability in certain design aspects: White labels may not be as visually appealing as clear labels, especially for products that require unique or eye-catching packaging.

Potential mismatch with product aesthetics: In some cases, the white label background may clash with the product aesthetics. For example, a high-end luxury product may look out of place with a plain white label.

Besides the strengths and weaknesses of these clear and white labels, you need to consider the specific application and industry. Remember that clear labels are ideal for showcasing the product, while white labels are better suited for labeling and tracking purposes.

How to Choose the Right Printer in Printing Clear or White Labels

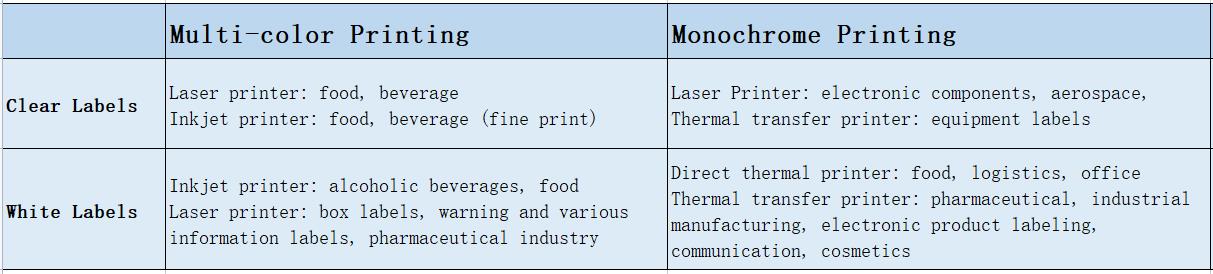

The next step is to choose the right type of label printers. There are generally four types of label printers - direct thermal, thermal transfer, inkjet, and laser printers, each one has its advantages. We highly recommend reading the article titled "Direct Thermal, Thermal Transfer, Inkjet, and Laser Label Printers: Which One to Choose?" to quickly grasp the unique features of each printer type.

a)One thing for sure, if you intent to print full-color labels, please choose inkjet and laser printers. Color laser printers are suitable for everyday multi-color label printing, however, if you would like to print some labels with high resolution photos, go with a inkjet printer.

b) In printing clear labels, you may select laser printers or thermal transfer label printers. And for single-color printing, thermal transfer printers is the preferred choice. These printers can apply to a wide variety of label materials, including clear synthetic fiber label and polypropylene labels.

Thermal transfer printers print high quality single-color labels withstanding heat, moisture exposure, chemical exposure and other harsh environments. Moreover, their produced labels can contain lots of fonts and number within a compact space, offering a nice resolution and crisp printing. Additionally, it’s very economic for large-volume printing with them compared with laser printing.

If you require the label printing with the smaller fonts and crisp text, laser printers is the right solution as they deliver higher resolution (up to 1200 dpi) than thermal transfer printers.

c) In printing white labels, thermal label printers are the leading roles except for color printing. No matter direct thermal or thermal transfer printers, both of them offer fast-speed and high-quality printing with good cost-benefit.

There are still some differences between them, such as applicable label materials, storage time, and printing accuracy. Generally, thermal transfer printers provide better details and higher resolution, and most importantly, their produced labels can survive harsh challenges and remain intact, therefore these labels are ideal for enduring applications such as permanent labeling, inventory barcode identification, telecom labels, asset tracking.

d) When putting all the criteria above into practice, you may still feel frustrated. Do not worry, below is a guiding diagram helping you.

e) Do not forget to consider the budget and cost of printing labels when choosing between these printers. And make sure the selected label printer is compatible with your existing software and equipment to avoid compatibility issues.

Clear and white label printers are both popular and versatile labeling options. By considering the specific application and industry, product packaging and design, label visibility and readability requirements, budget and cost considerations, and compatibility with existing equipment and systems, you can choose the right type of label printer for your business needs.